Glass cutting line machines represent the backbone of modern glass manufacturing and processing industries. These sophisticated systems automate the precise cutting of glass sheets into desired dimensions with remarkable accuracy and efficiency. By combining mechanical engineering, computer control systems, and specialized cutting tools, glass cutting line machines have revolutionized how manufacturers process glass for various applications, from architectural windows to automotive windshields and electronic displays. This article explores the intricate workings of these machines, their components, and the technology that makes them indispensable in today's glass industry.

What are the main components of a glass cutting line machine?

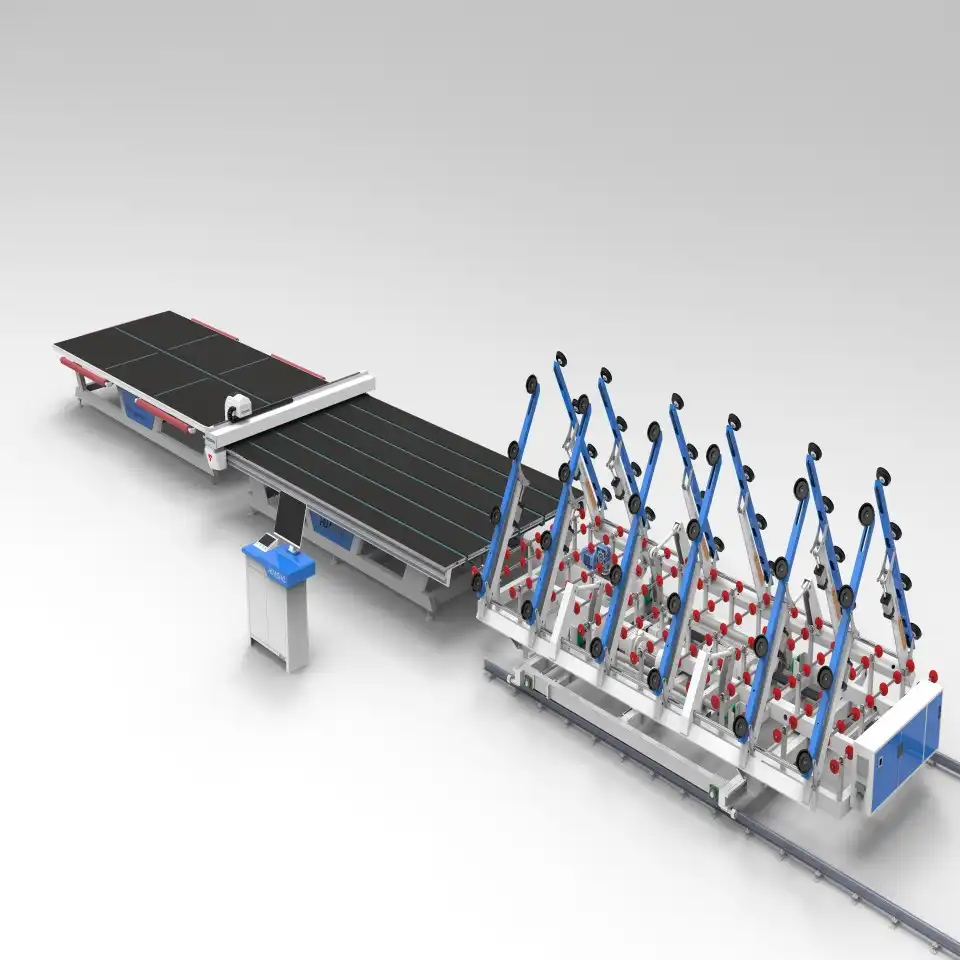

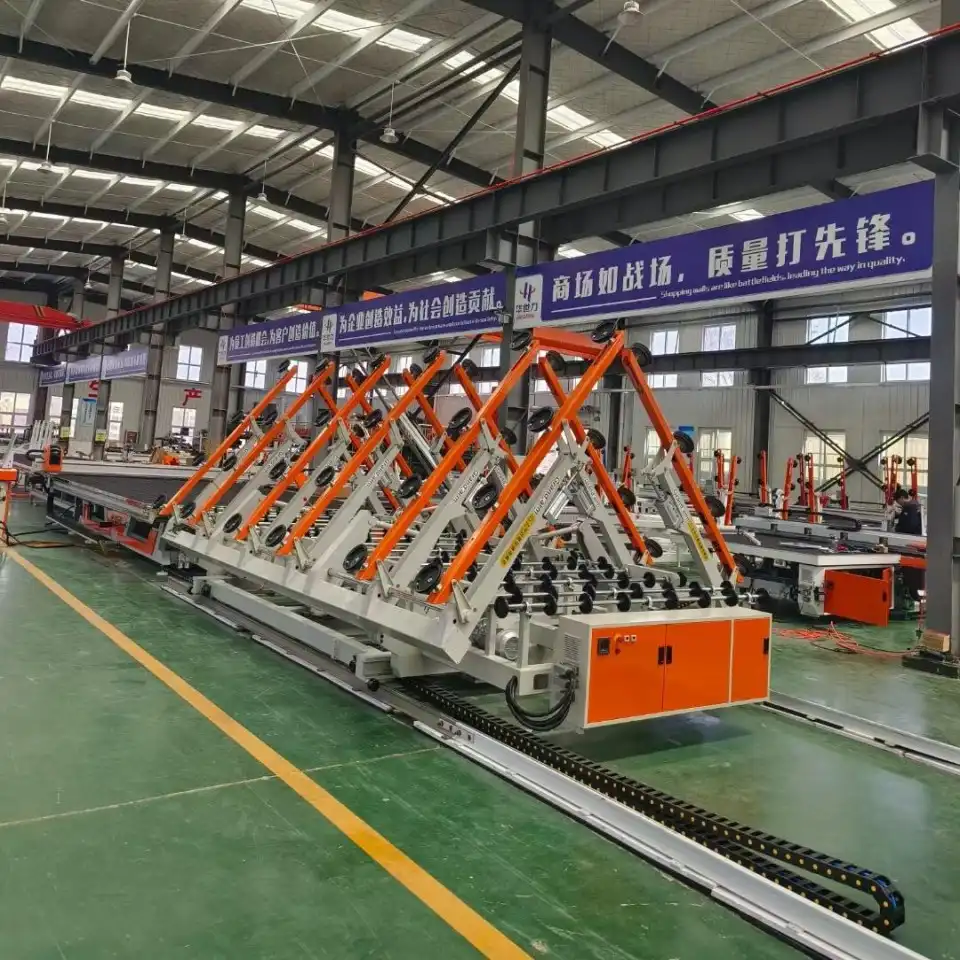

Cutting Tables and Conveyor Systems

The foundation of any glass cutting line machine is its cutting table and conveyor system. These components provide a stable platform for glass processing while facilitating smooth movement throughout the production line. The cutting table typically features an air cushion system that creates a thin layer of air between the glass and the table surface, reducing friction and preventing scratches on delicate glass sheets. Modern glass cutting line machines incorporate advanced conveyor systems with precision-controlled motors that ensure accurate positioning of glass sheets before and after cutting. These conveyor systems must maintain perfect synchronization with the cutting mechanisms to achieve precise dimensions. With glass cutting line machine technology continuously evolving, manufacturers now implement servo-driven conveyor systems that offer positional accuracy within fractions of a millimeter, ensuring consistent quality across high-volume production runs.

Cutting Heads and Tool Management

The cutting head represents the heart of a glass cutting line machine, housing the actual cutting tools that score the glass surface. These heads typically utilize industrial-grade diamond or carbide wheels that rotate at controlled speeds while applying calibrated pressure to the glass surface. Most advanced glass cutting line machines feature automatic tool changers that can select from multiple cutting wheels based on the specific glass type and thickness being processed. The cutting head moves along precision linear guides with extremely tight tolerances, allowing for complex cutting patterns including curves, circles, and intricate shapes. Sophisticated glass cutting line machines incorporate sensors that continuously monitor cutting wheel condition, automatically adjusting pressure and speed parameters or signaling when replacement is needed. This intelligent tool management significantly extends cutting wheel lifespan while maintaining consistent cut quality throughout production shifts.

Control Systems and Software Interface

Modern glass cutting line machines rely heavily on sophisticated control systems and user-friendly software interfaces. These systems coordinate all machine functions through programmable logic controllers (PLCs) and industrial computers. The software enables operators to upload cutting patterns, optimize material usage, and monitor production statistics in real-time. Glass cutting line machine control systems typically include algorithm-based optimization features that automatically arrange cutting patterns to maximize glass utilization and minimize waste. This nesting capability represents a critical advantage in production environments where material costs significantly impact profitability. Advanced glass cutting line machines incorporate Industry 4.0 connectivity, allowing integration with factory management systems for production tracking, preventive maintenance scheduling, and performance analytics. Some systems even use artificial intelligence to continuously improve cutting parameters based on historical performance data, resulting in progressively better quality and efficiency.

How does the glass cutting process work in automated production lines?

Scoring and Breaking Techniques

The fundamental principle behind glass cutting involves a two-stage process of scoring and breaking. During the scoring phase, the glass cutting line machine creates a precise microscopic fracture on the glass surface using a diamond or carbide wheel. This score line creates a controlled stress concentration that allows clean separation during the breaking phase. The glass cutting line machine applies calculated pressure along this score line, causing the glass to break cleanly along the intended path. Advanced glass cutting line machines precisely control both the scoring pressure and speed based on glass thickness, composition, and temperature to achieve optimal results. The most sophisticated systems employ variable pressure technology that automatically adjusts the scoring force as the cutting head navigates curves and corners, preventing common defects like overruns or incomplete breaks. Some specialized glass cutting line machines also incorporate heating elements that create thermal stress to facilitate clean breaks in particularly thick or laminated glass products.

Shape Cutting and Precision Control

Beyond simple straight cuts, modern glass cutting line machines excel at producing complex shapes with remarkable precision. Using computerized numerical control (CNC) technology, these machines can follow intricate cutting paths with deviations measured in micrometers. The glass cutting line machine accomplishes this through high-resolution encoders and servo motors that continuously monitor and adjust the cutting head's position. Special cutting templates and suction cups help secure irregularly shaped glass pieces during processing, preventing unwanted movement that could compromise precision. State-of-the-art glass cutting line machines now incorporate vision systems with high-resolution cameras that scan glass sheets before cutting, detecting imperfections or flaws that might affect cut quality. The machine's software then automatically adjusts cutting paths to avoid these areas or optimizes the cutting pattern to extract the maximum value from each glass sheet despite any defects.

Edge Processing and Quality Control

After cutting, many glass cutting line machines include integrated edge processing stations that finish the newly created edges. These stations may perform operations such as grinding, polishing, or applying edge treatments to ensure safety and structural integrity. The glass cutting line machine monitors edge quality through sensors that measure dimensions, detect chips or microfractures, and verify edge treatments meet specifications. Automated quality control systems within advanced glass cutting line machines employ laser measurement technology to verify final dimensions with exceptional accuracy. These systems can detect deviations as small as 0.01mm and automatically flag pieces that fall outside acceptable tolerance ranges. Modern glass cutting line machine systems also include wash stations that remove cutting fluid residue and glass particles before packaging or downstream processing. This integrated approach ensures that glass components leave the cutting line ready for immediate use in subsequent manufacturing processes.

What factors influence the efficiency of glass cutting line machines?

Glass Type and Thickness Considerations

Different glass varieties present unique challenges for cutting operations, requiring specific adaptations in glass cutting line machine parameters. Float glass, tempered glass, laminated glass, and specialty glasses each demand customized cutting approaches regarding speed, pressure, and tooling selection. The glass cutting line machine must adjust its operating parameters based on not just the glass type but also its thickness, which can range from less than 1mm for electronics applications to over 25mm for architectural projects. Advanced glass cutting line machines contain built-in glass libraries with optimized cutting parameters for hundreds of different glass specifications, eliminating guesswork and ensuring consistent results. Material-specific cutting wheels are automatically selected by the glass cutting line machine based on the programmed job requirements. For particularly challenging materials like ultra-thin display glass or chemically strengthened glass, specialized glass cutting line machines employ technologies such as laser cutting or water jet cutting instead of traditional mechanical methods.

Machine Calibration and Maintenance Requirements

Maintaining optimal performance in glass cutting line machines requires regular calibration and preventive maintenance. Even minor misalignments in cutting heads or conveyor systems can result in dimensional inaccuracies or edge defects. Professional technicians use specialized instruments to verify alignment, squareness, and parallelism across all glass cutting line machine components. Modern glass cutting line machines incorporate self-diagnostic capabilities that continuously monitor critical parameters like motor temperatures, air pressure, and hydraulic fluid levels. These systems can alert operators to potential issues before they impact production quality. Regular maintenance tasks for glass cutting line machines include replacing cutting wheels, cleaning sensors, lubricating moving parts, and updating control software. The most advanced glass cutting line machine systems now feature predictive maintenance capabilities, analyzing operational data to forecast when components are likely to fail, allowing maintenance to be scheduled during planned downtime rather than experiencing unexpected breakdowns.

Production Speed and Material Optimization

Production throughput represents a critical metric for glass cutting line machines, directly impacting manufacturing costs and capacity. Modern systems optimize cycle times through parallel processing, where multiple operations occur simultaneously across different stations. The glass cutting line machine software continuously calculates the most efficient cutting sequences and movement paths to minimize non-productive time between cuts. Material utilization efficiency is equally important, as glass typically represents 60-70% of production costs in many applications. Sophisticated glass cutting line machine software implements powerful nesting algorithms that can improve material yield by 5-15% compared to manual planning. These optimization engines consider factors such as glass sheet dimensions, required product sizes, grain direction, and quality zones to maximize yield. The most advanced glass cutting line machines incorporate real-time production analytics that provide managers with key performance indicators through dashboard interfaces. These systems track metrics like machine uptime, material efficiency, cycle times, and quality rates, allowing continuous improvement of the glass cutting operation.

Conclusion

Glass cutting line machines represent sophisticated manufacturing systems that combine precision mechanics, control technology, and specialized tooling to transform raw glass sheets into finished components with extraordinary accuracy. These versatile machines handle diverse glass types and thicknesses while optimizing material usage and maintaining consistent quality. As technology continues to advance, glass cutting line machines will likely incorporate more automation, artificial intelligence, and connectivity features to further enhance performance and flexibility in glass processing operations.

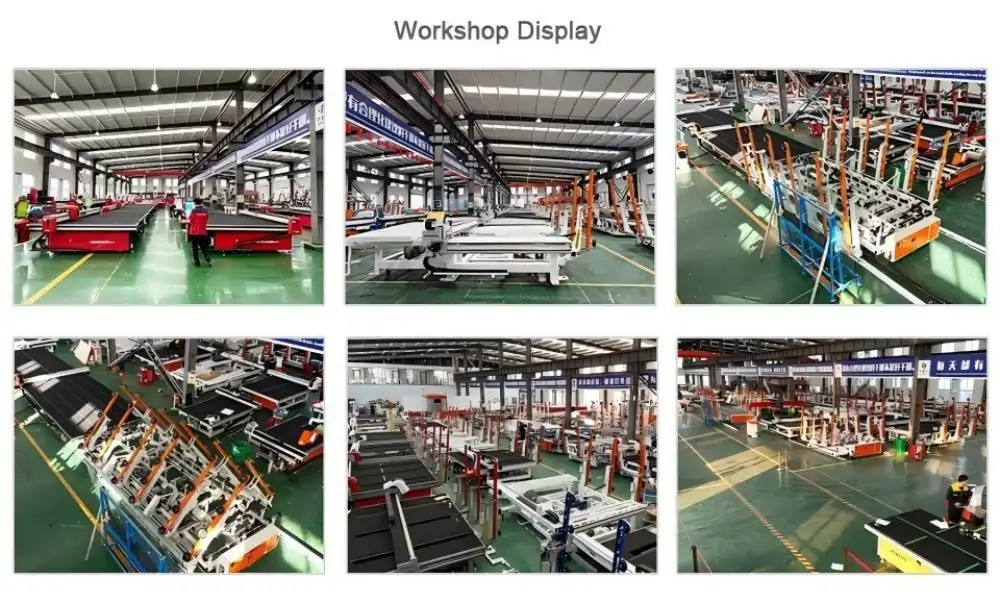

Shandong Huashil Automation Technology Co., Ltd. is a leading provider in the glass machinery and mechanical equipment industry, offering high-quality products and comprehensive solutions. With over ten years of export experience, the company boasts a mature R&D team, a reliable source factory, and a professional after-sales service team. Huashil's core services include OEM support, fast delivery, high cost performance, and dependable after-sales service. The company holds complete certifications, ensuring the highest standards of quality and reliability. If you are interested in exploring our products or wish to establish in-depth cooperation, please feel free to contact us at salescathy@sdhuashil.com for more information.

References

1. Johnson, M. R., & Williams, D. K. (2023). Advances in Automated Glass Processing Technology. Journal of Manufacturing Engineering, 45(3), 112-128.

2. Zhang, L., & Thompson, R. C. (2022). Precision Control Systems in Modern Glass Cutting Equipment. International Journal of Industrial Automation, 17(2), 89-104.

3. Peterson, A. L., Chen, H., & García, J. (2023). Material Optimization Algorithms for Glass Cutting Operations. Journal of Operations Research in Manufacturing, 12(4), 215-231.

4. Nakamura, S., & Wilson, E. (2024). Edge Quality Assessment in Automated Glass Processing. Quality Engineering Review, 29(1), 54-71.

5. Roberts, C. M., & Li, Y. (2023). Industry 4.0 Applications in Glass Manufacturing Lines. Smart Manufacturing Technologies, 8(2), 176-192.

6. Anderson, P. T., Müller, F., & Zhao, K. (2022). Comparative Analysis of Mechanical and Laser-Based Glass Cutting Technologies. Journal of Materials Processing Technology, 39(3), 302-317.