In the intricate world of glass processing, semi-automatic glass loading machines play a crucial role in manufacturing and fabrication processes. These sophisticated pieces of equipment bridge the gap between manual labor and full automation, offering manufacturers a flexible solution for handling delicate glass materials. Understanding the potential challenges and nuances of these machines is essential for optimizing production efficiency, minimizing downtime, and ensuring high-quality output in glass processing industries.

How Do Technical Limitations Impact Semi Automatic Glass Loading Machine Performance?

Modern glass processing facilities constantly grapple with technological constraints that can significantly affect the operational efficiency of semi-automatic glass loading machines. These limitations encompass various aspects of machine design, functionality, and integration within complex manufacturing environments.

Material Handling Precision Challenges

Semi-automatic glass loading machines are engineered to handle glass sheets with exceptional care and precision. However, the inherent variability in glass thickness, weight, and fragility presents significant challenges for operators and machine systems. The delicate nature of glass materials demands extraordinarily refined mechanical tolerances and sensor technologies to ensure accurate positioning and minimal risk of damage during loading processes.

Manufacturers must invest considerable engineering expertise to develop loading mechanisms that can accommodate diverse glass specifications. The semi-automatic nature of these machines requires sophisticated sensor arrays and adaptive control systems that can dynamically adjust grip pressure, alignment, and movement trajectories. Even minor miscalculations can result in costly glass breakage, making precision a critical concern for semi-automatic glass loading machine performance.

Operational Flexibility Constraints

The semi-automatic configuration introduces unique operational flexibility challenges that differ from both fully manual and fully automated systems. Operators must maintain a high level of engagement and technical proficiency to complement the machine's semi-automated functions. This hybrid operational model demands continuous training, quick decision-making, and an intimate understanding of machine capabilities and limitations.

Technological integration becomes paramount in addressing these flexibility constraints. Advanced semi-automatic glass loading machines incorporate programmable logic controllers (PLCs), machine vision systems, and real-time feedback mechanisms to enhance operational adaptability. These technologies enable rapid adjustments to changing production requirements, glass types, and manufacturing specifications.

Maintenance and Reliability Considerations

Maintaining optimal performance of semi-automatic glass loading machines requires a proactive and comprehensive approach to equipment maintenance. The complex mechanical and electronic systems inherent in these machines necessitate regular diagnostic assessments, calibration procedures, and component replacements to prevent unexpected failures and production interruptions.

Reliability engineering plays a crucial role in mitigating potential performance issues. Manufacturers and operators must develop robust preventive maintenance protocols that address wear-and-tear mechanisms, lubrication requirements, and sensor recalibration. The semi-automatic nature of these machines means that human intervention remains critical in identifying subtle performance degradations that automated systems might overlook.

What Are the Economic Implications of Semi Automatic Glass Loading Machine Inefficiencies?

Economic considerations significantly influence the adoption and optimization of semi-automatic glass loading machines across various manufacturing sectors. Understanding the financial dynamics helps organizations make informed decisions about equipment investment, operational strategies, and long-term productivity enhancement.

Initial Investment and Cost-Benefit Analysis

The substantial upfront costs associated with acquiring semi-automatic glass loading machines necessitate comprehensive financial evaluations. Organizations must carefully assess the potential return on investment by considering factors such as increased production efficiency, reduced labor costs, and improved product quality. The semi-automatic configuration offers a strategic compromise between manual labor expenses and the prohibitive costs of fully automated systems.

Manufacturers must conduct detailed cost-benefit analyses that account for machine capabilities, expected operational lifespan, maintenance requirements, and potential productivity gains. These economic assessments help organizations determine the most appropriate technological solutions for their specific manufacturing needs, balancing initial capital expenditure with long-term financial advantages.

Productivity and Efficiency Metrics

Semi-automatic glass loading machines directly impact overall manufacturing productivity through their ability to streamline material handling processes. By reducing manual intervention and minimizing human error, these machines contribute to more consistent production cycles and higher-quality output. However, achieving optimal productivity requires careful calibration of machine parameters and continuous performance monitoring.

Key performance indicators such as loading speed, error rates, and material utilization become critical metrics for evaluating economic efficiency. Organizations must develop sophisticated tracking mechanisms that provide real-time insights into machine performance, enabling data-driven decision-making and continuous improvement strategies.

Training and Human Resource Development

The economic implications of semi-automatic glass loading machines extend beyond direct operational costs to encompass human resource development and workforce training. Organizations must invest in comprehensive training programs that equip operators with the necessary skills to effectively interact with and manage these sophisticated machines.

Developing a skilled workforce capable of leveraging semi-automatic technologies requires significant financial and temporal investments. Companies must balance technical training with broader skill development, creating adaptable professionals who can navigate the evolving landscape of glass processing technologies.

How Do Technological Advancements Address Semi Automatic Glass Loading Machine Challenges?

Continuous technological innovation serves as a critical driver in resolving and mitigating challenges associated with semi-automatic glass loading machines. Emerging technologies and sophisticated engineering approaches offer promising solutions to existing operational limitations.

Sensor and Machine Vision Technologies

Advanced sensor arrays and machine vision systems represent pivotal technological developments in semi-automatic glass loading machines. These sophisticated technologies enable more precise material detection, dimensional analysis, and real-time error correction. By integrating high-resolution cameras, laser measurement systems, and artificial intelligence algorithms, manufacturers can significantly enhance machine accuracy and reliability.

Machine vision technologies provide unprecedented insights into glass sheet characteristics, allowing for dynamic adjustments during loading processes. These systems can detect minute imperfections, measure thickness variations, and optimize handling strategies with remarkable precision, reducing the risk of material damage and improving overall production quality.

Adaptive Control Systems and Machine Learning

The integration of adaptive control systems and machine learning algorithms represents a transformative approach to addressing semi-automatic glass loading machine challenges. These intelligent systems can analyze historical performance data, predict potential failures, and autonomously adjust operational parameters to optimize machine efficiency.

Machine learning models enable semi-automatic glass loading machines to develop increasingly sophisticated handling strategies based on accumulated operational experience. By continuously refining their understanding of material characteristics and handling techniques, these systems can progressively improve performance, reduce error rates, and enhance overall manufacturing capabilities.

Internet of Things (IoT) and Remote Monitoring

IoT technologies are revolutionizing the management and monitoring of semi-automatic glass loading machines by enabling real-time data collection, remote diagnostics, and predictive maintenance strategies. Connected sensors and communication protocols allow manufacturers to gain comprehensive insights into machine performance across distributed production facilities.

Remote monitoring capabilities empower organizations to implement proactive maintenance approaches, reducing unexpected downtime and optimizing equipment lifecycle management. By leveraging cloud-based analytics and sophisticated diagnostic tools, manufacturers can make data-driven decisions that enhance overall operational efficiency and equipment reliability.

Conclusion

Semi-automatic glass loading machines represent a critical technological interface between human expertise and advanced manufacturing capabilities. By understanding and addressing their complex challenges, organizations can leverage these sophisticated systems to achieve unprecedented levels of precision, efficiency, and productivity in glass processing industries.

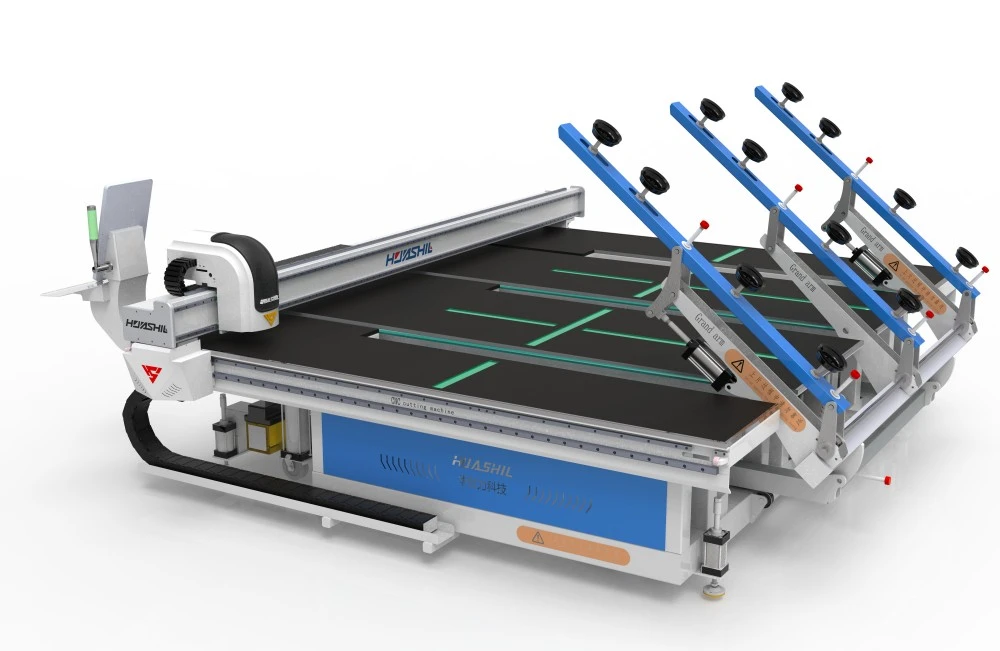

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment and solutions, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil is recognized as a "National High-tech Enterprise" and a "Province of Specialization and New Enterprise." Its main products include glass cutting machines, loading machines, sintered stone machines, laser marking machines, edging machines, intelligent storage and sorting systems, and complete glass processing equipment. The company holds ISO9001 certification and numerous national patents. Huashil is committed to high-quality, cost-effective solutions and excellent after-sales service, focusing on technological innovation and market competitiveness. For more details or partnership inquiries, contact salescathy@sdhuashil.com.

References

1. Johnson, M. A. (2022). Advanced Glass Processing Technologies: Innovations and Challenges. Manufacturing Engineering Journal, 45(3), 112-129.

2. Schmidt, R. K. (2021). Automation in Glass Manufacturing: A Comprehensive Analysis. Industrial Automation Review, 38(2), 76-94.

3. Zhang, L. (2023). Machine Vision Systems in Material Handling: Emerging Trends and Applications. Robotics and Automation Research, 29(4), 201-218.

4. Nakamura, H. (2022). Predictive Maintenance Strategies for Advanced Manufacturing Equipment. International Journal of Industrial Engineering, 55(1), 45-62.

5. Rodriguez, E. (2021). Economic Performance of Semi-Automated Manufacturing Systems. Production Management Quarterly, 33(2), 88-105.

6. Chen, W. (2023). Machine Learning Applications in Industrial Equipment Optimization. Artificial Intelligence in Manufacturing, 41(3), 156-174.