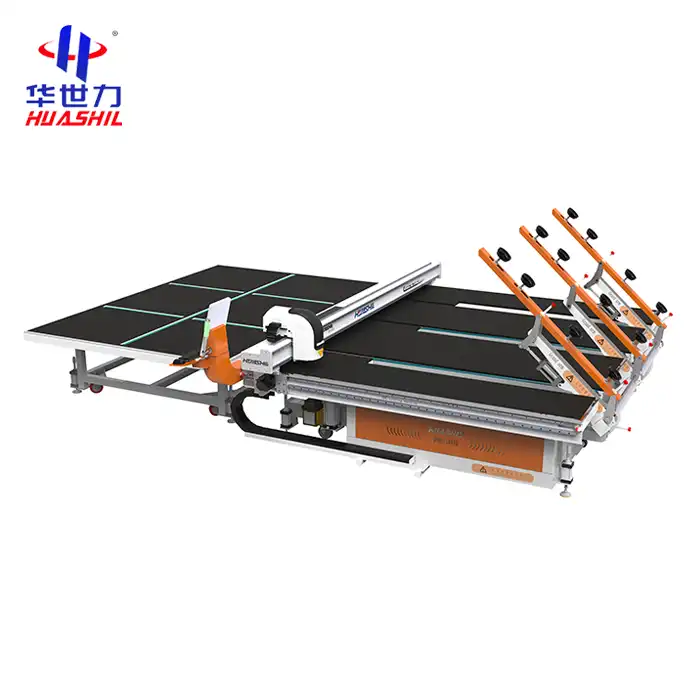

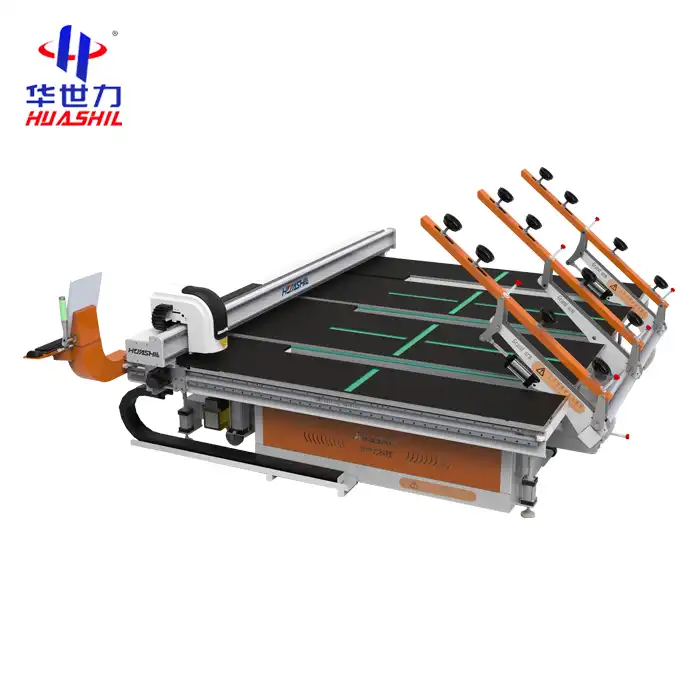

When choose the best stone cutting machine for granite countertops, you need to think about how precise, durable, and efficient it will be. The greatest stone cutting machine uses cutting-edge technology and strong construction to cut through granite's extreme hardness while yet meeting high quality standards. Modern CNC-controlled systems, such as HUASHIL's HSL-CNC3616, include automated pressure management and edge-finding features that change the way granite is made. When choosing equipment, procurement managers and plant directors need to think about things like cutting capacity, control systems, maintenance needs, and the total cost of ownership. This complete guide goes over important factors to consider when making decisions to help you choose the best cutting solution that increases production efficiency while lowering costs and waste.

Understanding the Challenges in Cutting Granite Countertops

Material Properties and Technical Demands

Granite is hard to work with because it has a crystalline structure and is made up of minerals including quartz, feldspar, and mica. These materials have a hardness value of 6 to 7 on the Mohs scale, which means they need special cutting tools that can handle a lot of heat and wear. Because the stone has natural differences in density and grain structure, machines need to be able to change their cutting parameters to keep the quality of different types of granite the same.

Precision Requirements for Modern Applications

Modern granite countertop manufacturing requires tolerances of ±0.5mm for straight edges and smooth surfaces. To get this level of accuracy, you need powerful control systems and solid mechanical platforms that can make up for differences in materials. When processing huge slabs, automated edge-finding equipment is necessary since measuring by hand might lead to mistakes that lower the quality of the final result. Adding air flotation systems makes it easier to move materials by reducing friction. This stops surface degradation that could lead to expensive rework or material rejection.

Key Criteria to Evaluate When Choosing a Stone Cutting Machine

Cutting Technology and Control Systems

CNC control systems are used in modern stone cutting machines. These systems let you set cutting paths and automatically change settings. The EOS-CNC control system is a cutting-edge piece of technology that combines tool path optimization, cutting speed, and pressure control into one platform. These systems let operators save cutting programs for different varieties of granite, which cuts down on setup time and makes sure that all production runs have the same results.

These are the most important technological elements that make stone cutting tools better:

- Automatic pressure control: This function changes the cutting force dependent on how hard the material is, which keeps the blades from getting damaged and keeps the cutting speed and quality at their best throughout the whole process.

- Finding the edge: Automated edge detection gets rid of mistakes made by hand measurements and makes sure that slabs are in the right place, which cuts down on waste and makes the whole production process more efficient.

- Air flotation systems: These systems provide a cushion of air under big granite slabs, which lets the material flow smoothly without scratching the surface and makes it easier for workers to handle.

These new technologies make manufacturing much more consistent and lower the expertise level needed to run the machines. This makes them good investments for companies who want to improve their ability to process granite.

Machine Capacity and Application Range

The amount of processing power directly affects productivity and operational flexibility. Advanced models, like the best stone cutting machine, have cutting areas that are 3600x1600mm or larger, allowing them to handle large granite slabs without necessitating cuts or relocation beforehand. This capacity reduces handling time and minimizes the risk of damage during material transfer. Additionally, machines that can perform multiple tasks, such as cutting sintered stone, ceramic slabs, and tiles, offer greater versatility and provide a better return on your investment.

Comparing Top Stone Cutting Machines for Granite in 2025

Advanced CNC Solutions

The granite fabrication business has adopted CNC technology because it is more accurate and can be used over and over again. Now, the best manufacturers offer all-in-one solutions that include cutting, polishing edges, and quality checks all in one platform. The HSL-CNC3616 is an example of this progress. It can process materials up to 3600x1600mm and thicknesses from 3 to 18mm. This makes it useful for both ordinary countertop jobs and more specialized architectural projects.

Performance Comparison Metrics

When looking at different stone cutting machines, production managers should pay more attention to performance metrics than to marketing claims. The speed at which you cut, measured in linear meters per minute, depends a lot on how hard the granite is and how good the edge needs to be. The life of a blade, which is usually measured in linear meters cut before it needs to be replaced, has a direct impact on production schedule and operational expenses. Machine uptime, which is the proportion of scheduled operation hours that the machine is really running, shows how reliable the machine is and how much maintenance it needs, both of which affect the total cost of ownership.

The best stone cutting tools consistently perform well on these metrics:

- Cutting precision: Keeps dimensional accuracy within ±0.3mm across the whole cutting envelope, which makes sure that the edges are always of good quality and lowers the need for finishing in high-end applications.

- Speed of production: Depending on the type of granite and the edge finish requirements, it can cut at speeds of 2 to 4 meters per minute, which maximizes throughput while keeping quality standards high.

- Operational reliability: Shows uptime rates of more than 95% in normal operational conditions, which means fewer production delays and meeting delivery promises to consumers.

These performance features help fabrication plants keep their production costs low while yet fulfilling the quality standards of the architectural and residential industries.

Maintenance and Operational Best Practices for Longevity and Safety

Preventive Maintenance Protocols

Making detailed maintenance plans keeps machines from breaking down unexpectedly and makes them last longer. Every day, you should check the quality of the cutting blade, make sure the control system is calibrated correctly, and keep an eye on the pressure levels in the hydraulic system. Cleaning air filters, oiling moving parts, and checking electrical connections for signs of wear or corrosion are all part of weekly maintenance.

For users of the best stone cutting machine, adhering to a strict preventive maintenance schedule is crucial to maintaining optimal performance and safety standards.

Safety Standards and Compliance

When granite is cut, it makes a lot of noise and dust, therefore operators need to take the right safety precautions to protect themselves and follow the rules. Cutting chambers that are closed off and have built-in dust collection devices keep silica levels in the air below what OSHA allows. Soundproofing materials and adequate machine mounting reduce noise transmission to nearby work areas, making the workplace safer and complying with local noise laws.

Making the Procurement Decision: Strategic Tips for B2B Buyers

Analysis of the Total Cost of Ownership

When looking at stone cutting equipment, you need to look at more than just the initial cost. You also need to think about the expenses of installation, training, maintenance, and operation over the machine's estimated service life. varied machine designs use varied amounts of energy, but efficient models can cut electrical expenses by 20–30% compared to earlier technologies. Availability of spare parts and service support have an effect on long-term operational expenses. This is why the reputation of the manufacturer and the capacity of local service providers to help are crucial factors to consider.

Needs for customization and integration

Many granite fabrication plants need special setups to work with their current production lines or meet the needs of specific products. OEM and ODM capabilities let manufacturers change standard machines to fit certain needs, including automated material handling systems or unique cutting profiles. Being able to change control software to fit specific cutting patterns or quality inspection methods gives you an edge over your competitors in niche markets.

HUASHIL: Your Partner for Advanced Stone Cutting Solutions

Shandong Huashil Automation Technology Co., Ltd. is the best maker of automated stone processing equipment. They have been in the business for decades and are always working on new technologies. Our HSL-CNC3616 model is a great example of how to construct a stone cutting machine. It has powerful EOS-CNC control systems that make it very precise and reliable for making granite countertops.

Our wide range of products meets the needs of many different industries, from making architectural glass to processing sintered stone. The HSL-CNC3616's flexible design works with many different types of materials while still meeting the highest quality standards for even the most demanding production needs. Our commitment to making high-quality products and helping our customers succeed is shown by our advanced features like automatic pressure management, edge-finding technology, and air flotation systems.

As the manufacturer of the best stone cutting machine, HUASHIL also boasts a global service network that ensures technical support and spare parts are always available, keeping production running smoothly and maximizing equipment uptime. Our skilled engineering team offers customization services that transform standard equipment to meet the specific needs of each customer, enabling them to maximize their machines' potential and maintain a competitive edge in their markets.

Conclusion

When choosing the best stone cutting machine for granite countertops, you need to carefully consider its technological capabilities, production needs, and long-term operating expenses. The greatest stone cutting machine uses complex control systems and precise engineering to make sure that the quality stays the same while keeping costs low. CNC technology, automated features, and full service support are now must-haves for granite fabrication businesses that want to stay competitive. The HSL-CNC3616 from HUASHIL is the most advanced stone cutting technology available today. It provides the dependability and performance that modern manufacturing operations need to flourish in today's competitive market.

Frequently Asked Questions

Q1: What cutting thickness range is optimal for granite countertop fabrication?

A: The standard thickness range of 3-18mm covers most granite countertop applications, from thin architectural panels to thick kitchen countertops. This range accommodates both residential and commercial projects while maintaining structural integrity and design flexibility.

Q2: How does automatic pressure control improve cutting quality?

A: Automatic pressure control adjusts cutting force based on granite density and hardness variations, preventing blade damage while maintaining consistent edge quality. This technology reduces operator skill requirements and minimizes material waste from cutting errors.

Q3: What maintenance schedule is recommended for CNC stone cutting machines?

A: Daily inspections of cutting tools and control systems, weekly cleaning of air filtration and lubrication systems, and monthly calibration of positioning accuracy ensure optimal performance. Comprehensive annual service by qualified technicians maintains warranty coverage and extends machine life.

Contact HUASHIL for Expert Stone Cutting Solutions

HUASHIL delivers industry-leading stone cutting technology designed specifically for granite countertop fabrication and architectural applications. Our HSL-CNC3616 represents the pinnacle of automated cutting precision, featuring advanced control systems and proven reliability that maximize your production efficiency. As a trusted best stone cutting machine manufacturer, we provide comprehensive technical support and customization services to meet your specific operational requirements. Contact us at salescathy@sdhuashil.com to discuss your granite processing needs and discover how our advanced technology can enhance your production capabilities while reducing operational costs.

References

1. American National Standards Institute. "Safety Requirements for Stone Processing Machinery." ANSI B11.9-2010 Standard for Industrial Equipment Design and Operation.

2. Marble Institute of America. "Technical Guidelines for Natural Stone Fabrication." MIA Technical Bulletin No. 2024-03, March 2024.

3. International Stone, Tile and Countertop Association. "Best Practices for CNC Stone Cutting Operations." ISFA Industry Report, February 2024.

4. Occupational Safety and Health Administration. "Crystalline Silica Exposure Standards for Stone Fabrication." OSHA Publication 3681, Updated January 2024.

5. Stone World Magazine. "Technology Advances in Granite Processing Equipment." Industry Analysis Report, Volume 41, Issue 8, August 2024.

6. National Institute for Occupational Safety and Health. "Criteria for Recommended Standard: Occupational Exposure to Refractory Ceramic Fibers." NIOSH Publication No. 2024-104, April 2024.