The glass industry has witnessed significant advancements in recent years, with the introduction of computer numerical control (CNC) technology revolutionizing the glass cutting process. CNC glass cutting machines have become increasingly popular, replacing traditional manual glass cutting machines in many manufacturing settings. But what exactly is the difference between these two types of machines, and how do they impact the glass cutting process?

Can a CNC Glass Cutting Line Improve Production Efficiency?

What are the Benefits of Using a CNC Glass Cutting Line?

A CNC glass cutting line is a highly automated system that uses computer-controlled machinery to cut glass with precision and accuracy. One of the primary benefits of using a CNC glass cutting line is its ability to improve production efficiency. By automating the cutting process, manufacturers can significantly reduce labor costs and increase productivity. CNC glass cutting lines can also optimize glass usage, minimizing waste and reducing material costs. Furthermore, these machines can be easily integrated into existing production lines, allowing for seamless workflow and increased throughput.

How Does a CNC Glass Cutting Line Enhance Accuracy?

CNC glass cutting lines are designed to provide exceptional accuracy and precision. By using advanced software and computer-controlled machinery, these systems can cut glass with intricate designs and complex shapes. The use of CNC technology eliminates human error, ensuring that every cut is accurate and consistent. This level of precision is particularly important in industries such as architecture and automotive, where glass is used in critical applications. With a CNC glass cutting line, manufacturers can produce high-quality glass products that meet the most stringent specifications.

What are the Key Features of a CNC Glass Cutting Line?

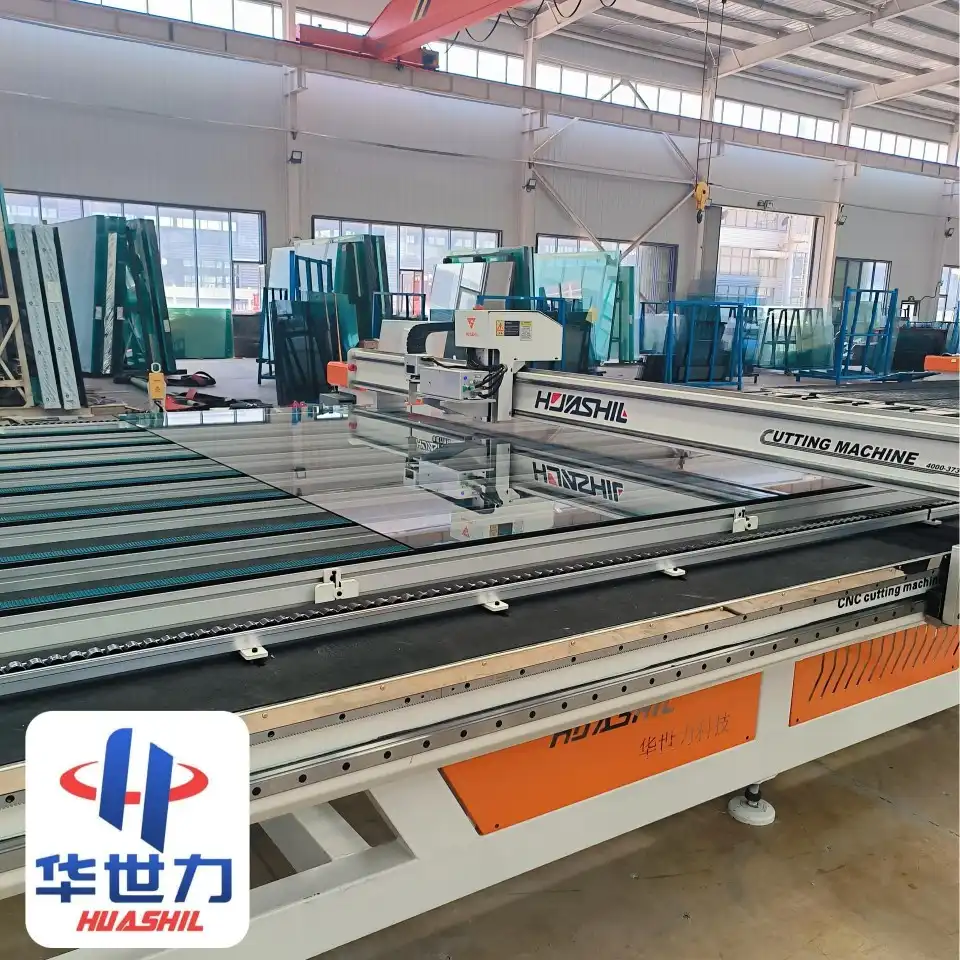

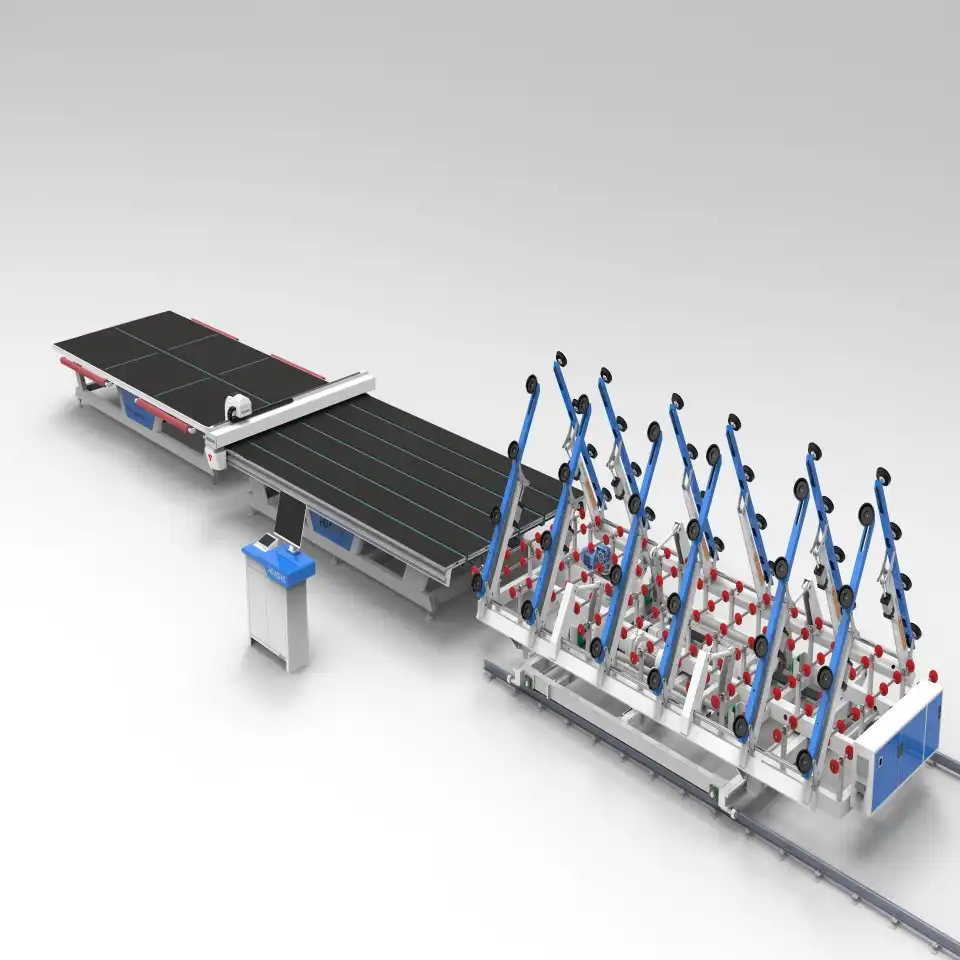

A typical CNC glass cutting line consists of several key components, including a cutting table, a CNC control system, and a glass handling system. The cutting table is designed to support large sheets of glass, while the CNC control system provides precise control over the cutting process. The glass handling system is responsible for loading and unloading glass sheets, minimizing manual handling and reducing the risk of damage. By integrating these components, a CNC glass cutting line can provide a highly efficient and automated glass cutting solution.

How Does a CNC Glass Cutting Line Compare to Manual Glass Cutting Machines in Terms of Cost?

What are the Initial Investment Costs for a CNC Glass Cutting Line?

While CNC glass cutting lines offer numerous benefits, they also require a significant initial investment. The cost of a CNC glass cutting line can vary widely, depending on the size and complexity of the system. However, manufacturers can expect to recoup their investment through increased productivity and reduced labor costs. In addition, CNC glass cutting lines can help reduce material waste and minimize the need for rework, further reducing costs.

How Do Operating Costs Compare Between CNC and Manual Glass Cutting Machines?

In terms of operating costs, CNC glass cutting lines are generally more cost-effective than manual glass cutting machines. By automating the cutting process, manufacturers can reduce labor costs and minimize the risk of human error. CNC glass cutting lines also require less maintenance than manual machines, reducing downtime and extending the lifespan of the equipment. While manual glass cutting machines may be less expensive to purchase upfront, they can be more costly to operate over time.

What are the Long-Term Cost Savings of Using a CNC Glass Cutting Line?

The long-term cost savings of using a CNC glass cutting line can be significant. By reducing labor costs, minimizing material waste, and optimizing glass usage, manufacturers can achieve substantial cost savings over time. In addition, CNC glass cutting lines can help improve product quality, reducing the need for rework and minimizing the risk of costly errors. By investing in a CNC glass cutting line, manufacturers can achieve a strong return on investment and improve their bottom line.

Is a CNC Glass Cutting Line Suitable for All Types of Glass Cutting Applications?

What Types of Glass Can be Cut Using a CNC Glass Cutting Line?

CNC glass cutting lines are highly versatile and can be used to cut a wide range of glass types, including float glass, tempered glass, and laminated glass. These systems can also be used to cut glass with complex shapes and intricate designs, making them ideal for a variety of applications. From architectural glass to automotive glass, CNC glass cutting lines can provide precise and accurate cuts for a range of industries.

Can a CNC Glass Cutting Line Handle Large or Complex Glass Sheets?

CNC glass cutting lines are designed to handle large and complex glass sheets with ease. These systems can be equipped with advanced glass handling systems, allowing for the safe and efficient loading and unloading of glass sheets. By using a CNC glass cutting line, manufacturers can process large glass sheets with precision and accuracy, minimizing the risk of damage or breakage.

Are There Any Limitations to Using a CNC Glass Cutting Line?

While CNC glass cutting lines offer numerous benefits, there are some limitations to their use. For example, these systems may not be suitable for very small or intricate glass cutting applications. Additionally, CNC glass cutting lines require significant upfront investment and may require specialized training to operate. However, for many manufacturers, the benefits of using a CNC glass cutting line far outweigh the limitations.

Conclusion

In conclusion, CNC glass cutting lines offer numerous benefits over traditional manual glass cutting machines, including improved production efficiency, enhanced accuracy, and reduced costs. By investing in a CNC glass cutting line, manufacturers can achieve a strong return on investment and improve their bottom line. Shandong Huashil Automation Technology Co., Ltd. is a leading provider in the glass machinery and mechanical equipment industry, offering high-quality products and comprehensive solutions. With over ten years of export experience, the company boasts a mature R&D team, a reliable source factory, and a professional after-sales service team. Huashil’s core services include OEM support, fast delivery, high cost performance, and dependable after-sales service. The company holds complete certifications, ensuring the highest standards of quality and reliability. If you are interested in exploring our products or wish to establish in-depth cooperation, please feel free to contact us at salescathy@sdhuashil.com for more information.

References

1. "Glass Cutting Machines: A Review of the Current Market Trends" by Glass Magazine, 2022.

2. "CNC Glass Cutting: A Guide to the Technology and its Applications" by Glass on Web, 2020.

3. "The Benefits of Using CNC Glass Cutting Machines in Manufacturing" by Automation World, 2019.

4. "Glass Cutting: A Comparison of Manual and CNC Methods" by Glass Processing, 2018.

5. "The Future of Glass Cutting: Trends and Technologies" by Glass International, 2020.

6. "CNC Glass Cutting Machines: A Review of the Current State of the Art" by Journal of Glass Science, 2021.