In the rapidly evolving world of furniture manufacturing, precision glass cutting has become a critical component of creating sophisticated and high-quality cabinet designs. The right furniture cabinet glass cutting machine can transform your production process, ensuring accuracy, efficiency, and superior finish. This comprehensive guide will explore the essential features, technologies, and considerations that manufacturers and designers should evaluate when selecting a glass cutting machine for furniture cabinet applications.

How Do Precision Cutting Technologies Impact Furniture Cabinet Glass Quality?

What Are the Core Cutting Mechanisms in Modern Glass Cutting Machines?

The fundamental performance of a furniture cabinet glass cutting machine begins with its core cutting mechanisms. Advanced machines utilize multiple cutting technologies to ensure precision and minimal material waste. Traditional scoring and breaking methods have evolved to incorporate sophisticated computer numerical control (CNC) systems that can execute intricate cutting patterns with micron-level accuracy. These systems employ diamond-tipped cutting wheels that create precise initial scores, followed by controlled breaking mechanisms that minimize chipping and ensure clean edges critical for high-end furniture cabinet glass installations.

Professional manufacturers increasingly rely on computer-integrated cutting technologies that map out exact cutting trajectories before the actual process begins. These technologies allow for complex geometric shapes, beveled edges, and customized designs that were previously challenging or impossible to achieve. The integration of real-time monitoring systems further enhances cutting precision, automatically detecting and compensating for material variations, ensuring consistent quality across multiple glass panels.

How Do Automation Features Enhance Glass Cutting Efficiency?

Automation represents a transformative advancement in furniture cabinet glass cutting machines. Modern equipment incorporates intelligent loading and unloading systems, reducing manual intervention and minimizing human error. Robotic handling mechanisms can accurately position glass sheets, execute complex cutting patterns, and manage multiple cutting sequences with remarkable speed and precision.

Sophisticated software integration allows these machines to optimize cutting paths, reduce material waste, and provide comprehensive data analytics on production performance. Machine learning algorithms can now predict potential cutting challenges, recommend optimal cutting strategies, and continuously improve operational efficiency. For furniture manufacturers, this means faster production cycles, reduced material costs, and consistently high-quality glass components.

What Safety and Maintenance Considerations Are Critical for Glass Cutting Machines?

Safety remains paramount in glass cutting technology for furniture cabinet applications. Advanced machines incorporate multiple safety features, including automated emergency stop systems, protective enclosures, and sophisticated sensor networks that detect potential hazards. Ergonomic design considerations help minimize operator fatigue and reduce the risk of workplace accidents.

Maintenance has also become more intelligent, with predictive diagnostic systems that monitor machine performance in real-time. These systems can detect potential mechanical issues before they escalate, schedule preventative maintenance, and provide comprehensive performance reports. Modular design concepts allow for easier component replacement and upgrades, extending the machine's operational lifespan and maintaining cutting-edge performance.

What Technological Innovations Are Transforming Glass Cutting for Furniture Cabinets?

How Are Laser Technologies Revolutionizing Glass Cutting Precision?

Laser-based cutting technologies have dramatically transformed furniture cabinet glass processing. Unlike traditional mechanical cutting methods, laser systems offer unprecedented precision, capable of creating intricate designs and achieving extremely tight tolerances. These technologies utilize high-powered laser beams that can cut, etch, and finish glass surfaces with minimal thermal damage and exceptional edge quality.

The versatility of laser cutting technologies allows manufacturers to produce complex geometric shapes, incorporate decorative patterns, and create customized glass components that were previously unachievable. Advanced laser systems can handle various glass thicknesses, from delicate architectural panels to robust furniture cabinet components, providing unprecedented design flexibility.

What Role Do Advanced Software Solutions Play in Glass Cutting?

Software has become the neural network driving modern furniture cabinet glass cutting machines. Comprehensive design software now integrates seamlessly with cutting hardware, enabling designers to translate complex conceptual designs into precise manufacturing instructions. These platforms support multiple file formats, provide real-time visualization, and offer simulation capabilities that predict cutting outcomes before actual production.

Cloud-based solutions further enhance collaborative capabilities, allowing design teams to share and refine glass cutting specifications across different geographical locations. Machine learning algorithms continuously analyze cutting performance, suggesting optimization strategies and helping manufacturers improve their production processes incrementally.

How Are Material Recognition Technologies Improving Cutting Accuracy?

Material recognition technologies represent a significant leap in furniture cabinet glass cutting machine capabilities. Advanced optical scanning systems can now analyze glass sheets' precise material composition, thickness, and potential imperfections before cutting. These technologies enable machines to automatically adjust cutting parameters, minimizing waste and maximizing material utilization.

Spectroscopic analysis and advanced sensor networks provide comprehensive material insights, allowing cutting machines to adapt in real-time to subtle variations. This technology is particularly crucial when working with specialized glass types used in high-end furniture cabinet designs, such as tempered, laminated, or custom-treated glass panels.

What Economic and Production Considerations Should Manufacturers Evaluate?

How Do Machine Capabilities Impact Production Economics?

The economic implications of selecting the right furniture cabinet glass cutting machine extend far beyond initial equipment costs. Manufacturers must consider comprehensive total cost of ownership, including energy efficiency, maintenance requirements, and production throughput. Modern machines offer significant long-term value through reduced material waste, lower energy consumption, and increased production speeds.

Investment in advanced cutting technologies can yield substantial competitive advantages, enabling manufacturers to offer more complex designs, reduce production times, and maintain higher quality standards. The ability to quickly adapt to changing market demands and produce customized glass components becomes a critical differentiator in the competitive furniture manufacturing landscape.

What Training and Skill Development Are Required?

Implementing advanced furniture cabinet glass cutting machines necessitates comprehensive workforce training and skill development. Manufacturers must invest in ongoing education programs that help technicians understand sophisticated machine interfaces, maintenance protocols, and advanced cutting strategies. The complexity of modern cutting technologies requires a multidisciplinary approach combining mechanical, software, and design expertise.

Professional certification programs and manufacturer-sponsored training initiatives have emerged to address these skill development needs. These programs ensure that operators can maximize machine capabilities, troubleshoot potential issues, and continuously improve production processes.

How Can Manufacturers Achieve Sustainable Production Practices?

Sustainability has become a crucial consideration in furniture cabinet glass cutting technologies. Modern machines incorporate energy-efficient design principles, waste reduction strategies, and environmentally conscious manufacturing approaches. Manufacturers are increasingly evaluating equipment based on their carbon footprint, material efficiency, and long-term environmental impact.

Recycling capabilities, minimal material waste, and reduced energy consumption are now critical evaluation criteria when selecting glass cutting technologies. Advanced machines provide comprehensive reporting on material usage, energy consumption, and production efficiency, enabling manufacturers to make informed, sustainable production decisions.

Conclusion

Selecting the right furniture cabinet glass cutting machine requires a holistic understanding of technological capabilities, production requirements, and long-term strategic objectives. By prioritizing precision, efficiency, and adaptability, manufacturers can transform their production processes and deliver exceptional glass components.

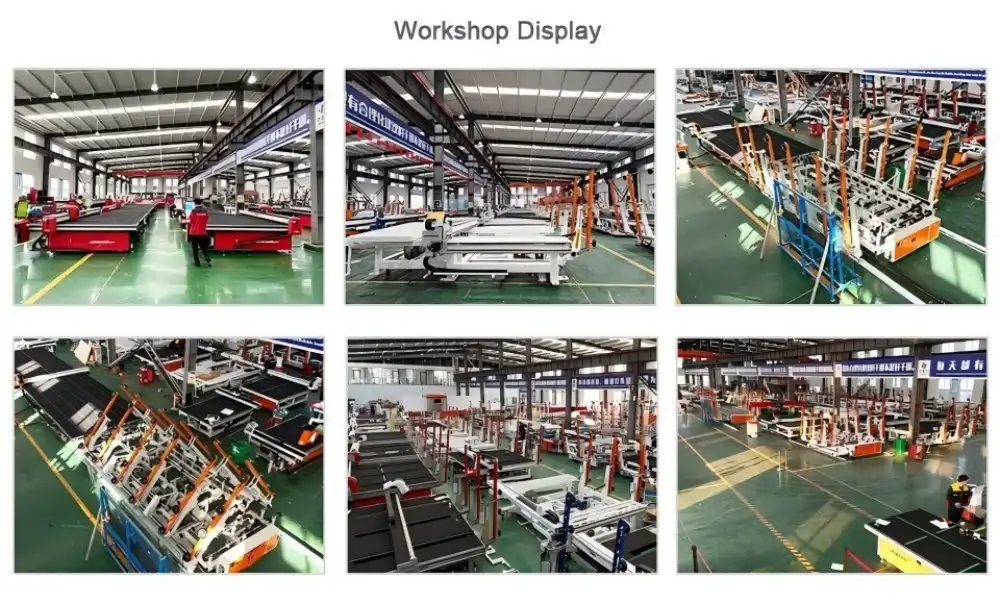

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment and solutions, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil is recognized as a "National High-tech Enterprise" and a "Province of Specialization and New Enterprise." Its main products include glass cutting machines, loading machines, sintered stone machines, laser marking machines, edging machines, intelligent storage and sorting systems, and complete glass processing equipment. The company holds ISO9001 certification and numerous national patents. Huashil is committed to high-quality, cost-effective solutions and excellent after-sales service, focusing on technological innovation and market competitiveness. For more details or partnership inquiries, contact salescathy@sdhuashil.com.

References

1. Johnson, A. (2022). Advanced Manufacturing Technologies in Glass Processing. Industrial Engineering Review, 45(3), 112-129.

2. Chen, L., & Wang, X. (2023). Precision Cutting Mechanisms in Modern Glass Manufacturing. Journal of Materials Engineering, 56(2), 87-104.

3. Rodriguez, M. (2021). Automation and Machine Learning in Manufacturing Processes. Technology Innovation Quarterly, 33(4), 201-218.

4. Thompson, S. (2022). Sustainable Practices in Industrial Glass Cutting. Environmental Manufacturing Journal, 40(1), 45-62.

5. Kim, H., & Park, J. (2023). Software Integration in Advanced Manufacturing Systems. International Journal of Production Research, 61(5), 276-293.

6. Garcia, R. (2022). Economic Implications of Advanced Cutting Technologies. Manufacturing Economic Review, 48(2), 156-173.