Glass cutting line machines are sophisticated systems designed to automate the glass cutting process in manufacturing facilities. These specialized machines combine mechanical precision with advanced technology to efficiently cut glass sheets into desired dimensions with exceptional accuracy. Understanding the key components of these machines is essential for anyone involved in glass processing industries, from facility managers to technicians and buyers considering investments in new equipment.

How does a glass cutting line machine improve production efficiency?

Automation and Labor Reduction

Glass cutting line machines significantly improve production efficiency by automating processes that would otherwise require manual labor. These sophisticated systems can handle large volumes of glass sheets continuously with minimal human intervention. The automation capabilities of a glass cutting line machine reduce the need for multiple operators and minimize the risk of human error during the cutting process. A modern glass cutting line machine can be programmed to execute complex cutting patterns consistently across hundreds or thousands of glass sheets, maintaining the same level of precision throughout extended production runs. This automation not only increases throughput but also allows manufacturers to allocate their workforce to other value-adding activities within the production facility.

Speed and Precision Advantages

When it comes to production speed, glass cutting line machines offer remarkable advantages over traditional methods. These machines can process glass sheets at rates that would be impossible to achieve manually, with some advanced systems capable of cutting multiple sheets simultaneously. The precision engineering in a glass cutting line machine ensures that each cut meets exact specifications, with tolerances often measured in fractions of a millimeter. This level of accuracy is crucial for applications such as architectural glass, automotive windshields, and electronic displays where dimensions must be perfectly consistent. The combination of speed and precision in modern glass cutting line machines allows manufacturers to meet demanding production schedules while maintaining exceptional quality standards that satisfy the most exacting client requirements.

Integration with Production Management Systems

Modern glass cutting line machines excel at integration with broader production management systems, creating streamlined workflows that maximize efficiency. These machines can be connected to enterprise resource planning (ERP) systems and manufacturing execution systems (MES) to enable real-time production tracking and optimization. When a glass cutting line machine is integrated into the broader production ecosystem, it can receive cutting instructions directly from design software, eliminating manual data entry and reducing setup time between batches. The machine can also relay performance data, material usage statistics, and maintenance needs back to the management system, allowing for proactive decision-making. This integration enables just-in-time production strategies that minimize inventory costs while ensuring that customer orders are fulfilled precisely and on schedule, representing a significant competitive advantage in today's fast-paced manufacturing environment.

What factors should be considered when choosing a glass cutting line machine?

Production Volume Requirements

Determining your production volume requirements is a crucial first step when selecting a glass cutting line machine. Manufacturers must carefully analyze their current and projected production needs to ensure they invest in equipment with appropriate capacity. Entry-level glass cutting line machines might handle 2,000-3,000 square meters of glass per shift, while high-capacity industrial systems can process over 10,000 square meters in the same timeframe. It's important to consider not just average production volumes but also peak demands and seasonal variations that might strain equipment capacity. Choosing a glass cutting line machine with slightly more capacity than your immediate needs provides room for business growth without requiring premature equipment replacement. Additionally, factors such as the thickness range of glass to be processed and the complexity of cutting patterns will impact the effective throughput of any glass cutting line machine, so these specifications must be matched carefully to your production requirements to avoid creating bottlenecks in your manufacturing process.

Space and Installation Requirements

The physical footprint and installation requirements of a glass cutting line machine represent significant considerations that shouldn't be overlooked during the selection process. These machines typically require substantial floor space, with complete systems potentially extending 20-30 meters in length and 5-8 meters in width. Beyond the machine's dimensions, adequate clearance must be provided for material handling, operator movement, and maintenance access. Installation of a glass cutting line machine often necessitates specific environmental conditions, including level flooring capable of supporting several tons of weight, regulated temperature and humidity levels to ensure optimal operation, and appropriate electrical service to power the system's components. Some advanced glass cutting line machines may also require compressed air systems or specialized cooling infrastructure. Manufacturers should work closely with equipment suppliers to develop detailed layout plans and prepare their facilities appropriately before delivery of the machine, potentially including facility modifications that might add to the total project timeline and cost.

Total Cost of Ownership Analysis

When evaluating glass cutting line machines, looking beyond the initial purchase price to understand the total cost of ownership (TCO) will reveal the true long-term value of each option. The acquisition cost of a glass cutting line machine typically represents only 40-60% of the total lifetime expenses associated with the equipment. Operating costs include energy consumption, which can vary significantly between models; some energy-efficient glass cutting line machines may consume 15-30% less electricity than standard versions, yielding substantial savings over time. Maintenance requirements also differ across manufacturers and models, with some glass cutting line machines designed for easy access to components and simplified troubleshooting that reduces downtime and service expenses. Consumable items such as cutting wheels, lubricants, and filters represent ongoing costs that accumulate over years of operation. Additionally, software licensing fees and potential upgrade costs should be factored into the TCO calculation. The expected service life of the glass cutting line machine, typically 10-15 years for quality equipment, provides the timeframe for amortizing these costs and determining the true value proposition of each option under consideration.

How is maintenance performed on glass cutting line machines?

Regular Maintenance Schedules

Implementing a rigorous maintenance schedule is fundamental to ensuring the longevity and optimal performance of any glass cutting line machine. These sophisticated systems require systematic care to prevent unexpected downtime and maintain cutting precision. Daily maintenance tasks typically include cleaning the cutting surface, checking fluid levels, and inspecting cutting wheels for signs of wear. Weekly maintenance procedures for a glass cutting line machine often involve lubricating moving parts, calibrating alignment systems, and testing safety mechanisms to ensure they're functioning properly. Monthly routines might include more thorough inspections of electrical components, replacement of filters, and verification of software systems. Many manufacturers recommend quarterly preventive maintenance visits from specialized technicians who can perform deeper diagnostics on the glass cutting line machine, including checking the accuracy of positioning systems, updating software, and preemptively replacing parts approaching the end of their service life. Maintaining detailed records of all maintenance activities creates a valuable history that can help identify recurring issues and optimize the maintenance schedule specifically for your glass cutting line machine's operating conditions and production demands.

Common Troubleshooting Techniques

Effective troubleshooting is essential for minimizing downtime when issues arise with a glass cutting line machine. Operators should be trained to recognize warning signs such as unusual noises, vibrations, or inconsistencies in cut quality that might indicate developing problems. When electrical issues occur in a glass cutting line machine, systematic checking of power supplies, connections, and control boards can often isolate the fault. For mechanical problems, examining drive systems, bearings, and alignment mechanisms frequently reveals the source of difficulties. Software-related issues in modern glass cutting line machines can sometimes be resolved through restart procedures or by restoring backup configurations. Many contemporary glass cutting line machines include self-diagnostic capabilities that can pinpoint specific components requiring attention, displaying error codes that reference the machine's documentation. Remote diagnostics features allow manufacturers' technical support teams to connect to the glass cutting line machine via secure internet connections, analyzing performance data and suggesting solutions without waiting for an on-site visit. Creating a troubleshooting decision tree specific to your glass cutting line machine model can help operators respond quickly and appropriately to common issues, potentially resolving problems before they escalate into major failures requiring extensive repairs.

Replacement Parts and Service Support

Access to quality replacement parts and reliable service support significantly impacts the operational reliability of a glass cutting line machine throughout its service life. When selecting a machine, evaluating the manufacturer's parts supply network becomes a critical consideration. Leading manufacturers maintain comprehensive inventories of common wear items for their glass cutting line machines, enabling rapid shipping of necessary components when replacements are needed. The availability of local service technicians specifically trained on your model of glass cutting line machine can dramatically reduce downtime during repairs, with some manufacturers offering service response guarantees within 24-48 hours. Service contracts for glass cutting line machines typically offer different levels of coverage, potentially including routine maintenance visits, emergency repair services, and even temporary replacement of critical components while repairs are completed. Many glass cutting line machine manufacturers now offer predictive maintenance programs that utilize real-time monitoring to identify components showing signs of deterioration before they fail completely. When evaluating these service options, manufacturers should consider not just the immediate costs but also the potential production losses associated with extended downtime if service support is inadequate or replacement parts are difficult to obtain for their specific glass cutting line machine model.

Conclusion

Glass cutting line machines represent a significant investment in production capability, combining multiple sophisticated components to deliver precision, efficiency, and reliability in glass processing operations. By understanding the key components, selection factors, and maintenance requirements, manufacturers can make informed decisions that optimize their glass processing capabilities and maintain competitive advantages. Proper selection, operation, and maintenance of these systems contribute significantly to production quality, throughput, and overall manufacturing success.

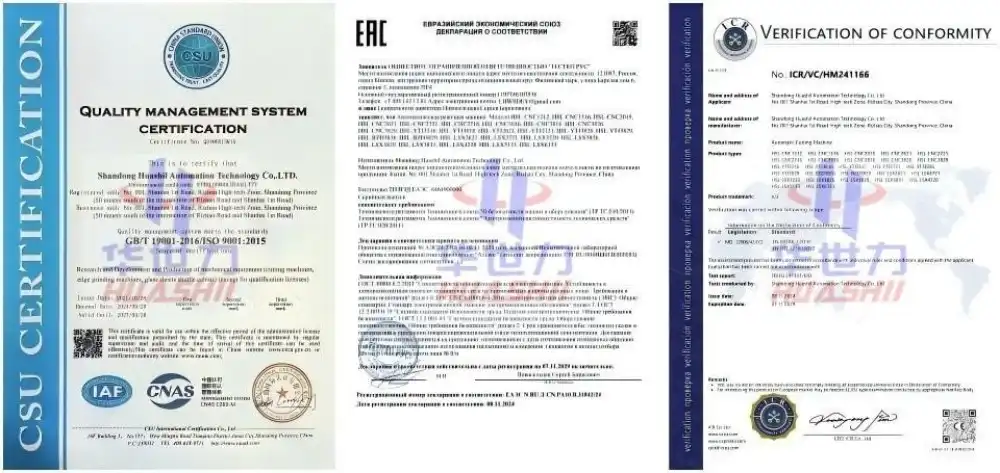

Shandong Huashil Automation Technology Co., Ltd. is a leading provider in the glass machinery and mechanical equipment industry, offering high-quality products and comprehensive solutions. With over ten years of export experience, the company boasts a mature R&D team, a reliable source factory, and a professional after-sales service team. Huashil's core services include OEM support, fast delivery, high cost performance, and dependable after-sales service. The company holds complete certifications, ensuring the highest standards of quality and reliability. If you are interested in exploring our products or wish to establish in-depth cooperation, please feel free to contact us at salescathy@sdhuashil.com for more information.

References

1. Zhang, L., & Wang, H. (2023). Advances in Automated Glass Processing: A Comprehensive Review of Cutting Line Technologies. Journal of Manufacturing Systems, 65(4), 218-233.

2. Brown, M. C., & Johnson, P. T. (2022). Industrial Glass Processing Equipment: Selection, Operation, and Maintenance Guidelines. Industrial Machinery Press, London.

3. Hernandez, R., & Smith, K. (2024). Energy Efficiency in Glass Manufacturing: Equipment Optimization Strategies. Sustainable Manufacturing Review, 18(2), 142-157.

4. Li, Y., Chen, J., & Davis, T. (2021). Integration of Industry 4.0 Technologies in Glass Production Lines: Case Studies and Best Practices. International Journal of Production Research, 59(7), 1879-1893.

5. Wilson, E. R., & Thompson, C. S. (2023). Maintenance Optimization for Automated Glass Processing Equipment. Journal of Manufacturing Maintenance, 12(3), 305-320.

6. Nakamura, T., & Garcia, A. D. (2022). Precision Engineering in Modern Glass Cutting Technologies: Principles and Applications. Engineering Process Technology, 47(5), 423-438.