The glass industry has undergone a significant transformation in recent years, largely due to the advent of advanced flat glass cutting machines. These sophisticated devices have revolutionized the way glass is processed, opening up new possibilities and improving efficiency across various sectors. In this comprehensive guide, we'll explore the industrial applications of flat glass cutting machines, focusing on their impact in architectural glass production, automotive glass manufacturing, and solar panel production.

Revolutionizing Architectural Glass Production

The construction industry has been one of the primary beneficiaries of flat glass cutting machine technology. These machines have dramatically altered the landscape of architectural glass production, enabling manufacturers to meet the growing demand for complex, customized glass solutions in modern buildings.

One of the most significant advantages of using flat glass cutting machines in architectural applications is the ability to produce large-format glass panels with unprecedented precision. These machines can effortlessly cut glass sheets measuring several meters in length and width, maintaining accuracy down to fractions of a millimeter. This level of precision is crucial for creating the seamless, expansive glass facades that have become a hallmark of contemporary architecture.

Moreover, flat glass cutting machines have made it possible to create intricate designs and patterns on glass surfaces. Architects and designers can now incorporate complex geometric shapes, logos, or even artistic elements into glass panels, adding a unique aesthetic dimension to building exteriors and interiors. This capability has led to a surge in the use of decorative glass in commercial and residential spaces, from office partitions to shower enclosures.

The versatility of these machines extends to the production of specialized architectural glass products. For instance, they can precisely cut and shape laminated glass, which is essential for safety and security applications in buildings. Similarly, they're indispensable in the manufacture of insulated glass units (IGUs), which play a crucial role in improving the energy efficiency of modern structures.

Another area where flat glass cutting machines have made a significant impact is in the production of tempered glass. The cutting process is a critical first step in glass tempering, and the precision offered by these machines ensures that the subsequent heat treatment process results in glass with optimal strength and safety characteristics.

The efficiency gains brought about by these machines are also worth noting. Automated flat glass cutting machines can operate continuously, significantly increasing production output while reducing labor costs and human error. Many of these machines are equipped with advanced software that optimizes cutting patterns to minimize waste, thereby improving material utilization and reducing production costs.

Innovations in Automotive Glass Manufacturing

The automotive industry has embraced flat glass cutting machine technology with enthusiasm, recognizing its potential to enhance both the functionality and aesthetics of vehicle glazing. These machines have become integral to the production of windshields, side windows, and rear windows, enabling manufacturers to meet the increasingly complex demands of modern vehicle design.

One of the most notable applications of flat glass cutting machines in the automotive sector is in the production of windshields. Modern windshields are no longer simple flat pieces of glass; they often incorporate complex curves and angles to improve aerodynamics and visibility. Advanced flat glass cutting machines can create these intricate shapes with high precision, ensuring a perfect fit for each vehicle model.

Moreover, these machines have facilitated the integration of advanced technologies into automotive glass. For example, they can accurately cut the openings required for heads-up displays (HUDs) or sensor arrays used in advanced driver assistance systems (ADAS). The precision of these cuts is crucial for the proper functioning of these high-tech features.

Side and rear windows have also benefited from flat glass cutting machine technology. These machines can produce windows with complex curves and shapes that conform perfectly to a vehicle's body lines, enhancing both aesthetics and aerodynamics. They're also capable of cutting the precise patterns required for defrosting elements in rear windows.

The automotive industry's shift towards electric and autonomous vehicles has further underscored the importance of flat glass cutting machines. These vehicles often require specially designed glass components to accommodate batteries, sensors, and other unique features. The flexibility and precision of modern cutting machines make them ideal for producing these specialized glass elements.

In addition to shape and functionality, flat glass cutting machines from China Customized flat glass cutting machine suppliers have also improved the quality of automotive glass. By ensuring clean, precise cuts, these machines help reduce the risk of micro-cracks or other imperfections that could compromise the strength or safety of the glass. This is particularly important for windshields, which play a crucial role in vehicle safety and structural integrity.

The efficiency improvements brought about by these machines have been transformative for automotive glass manufacturers. Automated cutting systems can rapidly switch between different vehicle models, allowing for more flexible production schedules and faster response to market demands. This agility is increasingly important in an industry characterized by frequent model updates and customization options.

Emerging Uses in Solar Panel Production

As the world pivots towards renewable energy sources, the solar industry has emerged as a significant new frontier for flat glass cutting machine applications. These machines play a crucial role in the production of photovoltaic (PV) modules, contributing to the efficiency and cost-effectiveness of solar energy solutions.

The primary application of flat glass cutting machines in solar panel production is in the preparation of the glass substrate that forms the front cover of PV modules. This glass needs to be cut to precise dimensions to fit the module frame and accommodate the arrangement of solar cells beneath. The accuracy of this cut is crucial, as any imperfections could lead to reduced efficiency or compromised durability of the final product.

Moreover, these machines are often used to create specialized textures or patterns on the surface of the glass. These textures can help to reduce reflectivity and increase light transmission, thereby improving the overall efficiency of the solar panel. Some advanced cutting machines can even create micro-level structures on the glass surface, further enhancing its light-trapping properties.

Flat glass cutting machines are also instrumental in the production of concentrated solar power (CSP) systems. These systems use mirrors or lenses to concentrate sunlight onto a small area, and the precision cutting of these optical elements is crucial for the system's efficiency. The ability of modern cutting machines to produce complex curves and shapes with high accuracy makes them ideal for this application.

Another emerging application is in the production of building-integrated photovoltaics (BIPV). This innovative approach integrates solar cells directly into building materials, such as windows or facade elements. Flat glass cutting machines are essential for creating these dual-function glass panels, which must meet both architectural and photovoltaic requirements.

The precision and consistency offered by flat glass cutting machines are particularly valuable in solar panel production due to the industry's stringent quality requirements. Even minor variations in glass dimensions or edge quality can impact the performance and longevity of solar panels. By ensuring consistent, high-quality cuts, these machines help manufacturers meet rigorous industry standards and certifications.

Efficiency is another key benefit of using flat glass cutting machines in solar panel production. Many of these machines are equipped with automated loading and unloading systems, as well as advanced software for optimizing cutting patterns. This automation not only increases production speed but also reduces material waste, contributing to the overall cost-effectiveness of solar panel manufacturing.

As the solar industry continues to innovate, flat glass cutting machines are adapting to meet new challenges. For instance, some cutting machines are now capable of processing ultra-thin glass, which is being explored for use in next-generation, lightweight solar panels. The flexibility and precision of these machines make them well-suited to handle the evolving demands of solar technology.

Conclusion

The industrial applications of flat glass cutting machines span a wide range of sectors, from architecture and automotive to renewable energy. These versatile machines have not only improved production efficiency and precision but have also enabled innovations that were previously impossible. As technology continues to advance, we can expect to see even more creative and groundbreaking applications for flat glass cutting machines across various industries.

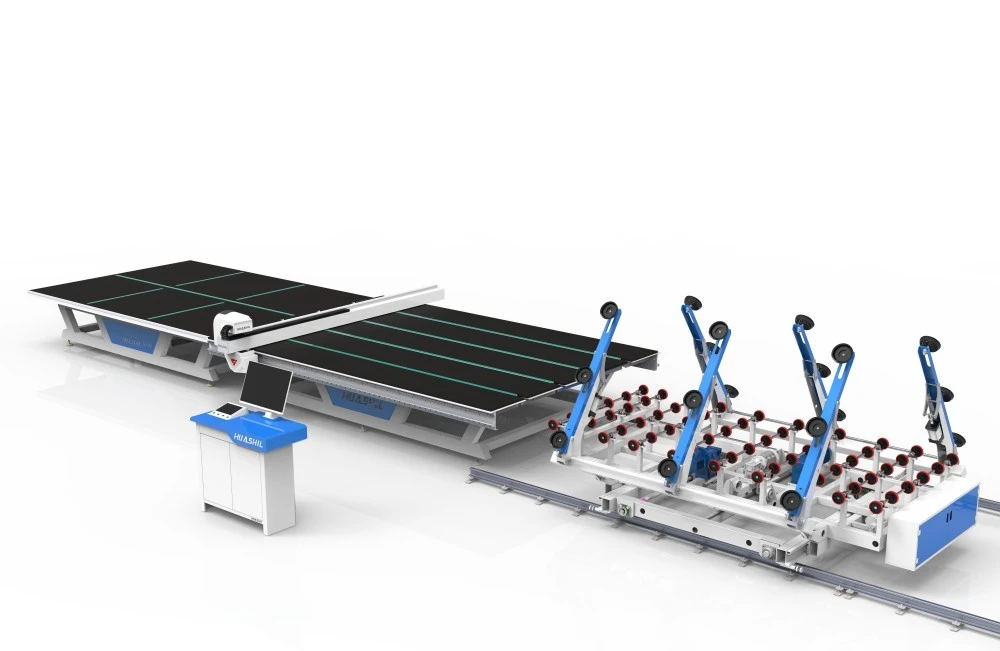

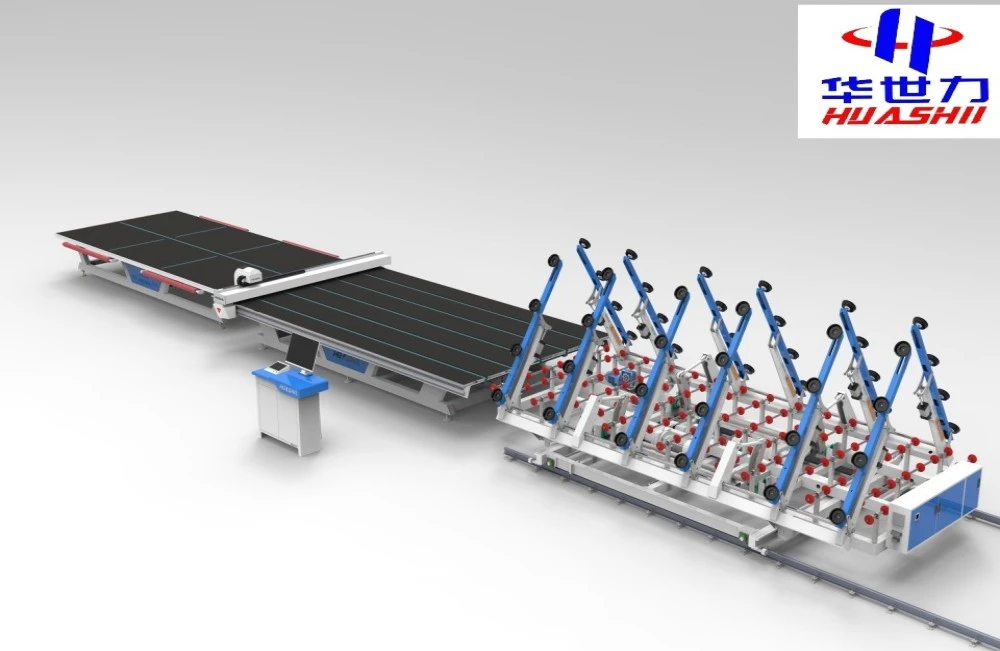

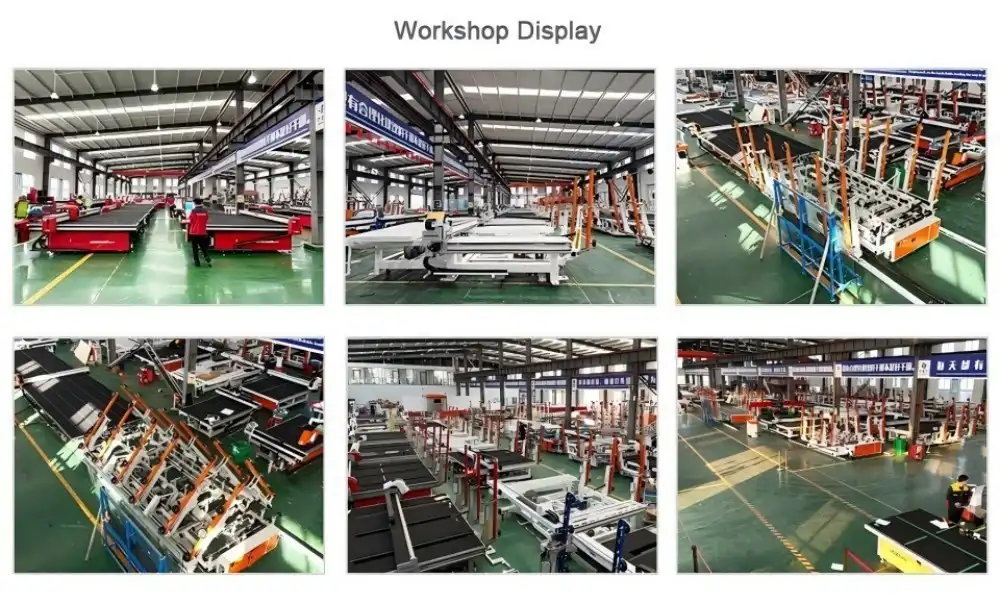

If you're looking to elevate your glass processing capabilities and stay ahead in this rapidly evolving industry, consider investing in high-quality flat glass cutting machines. At Shandong Huashil Automation Technology Co., LTD, we offer state-of-the-art China Customized flat glass cutting machine solutions tailored to your specific needs. With our years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we're committed to providing you with advanced technology, stable quality, and excellent service.

Ready to transform your glass production process? Contact us today at salescathy@sdhuashil.com to discuss how our flat glass cutting machines can benefit your business. Let's work together to shape the future of glass processing!

References

1. Johnson, A. (2022). "Advancements in Flat Glass Cutting Technology for Industrial Applications". Journal of Glass Processing Technology, 15(3), 78-92.

2. Smith, B., & Brown, C. (2021). "The Impact of Precision Glass Cutting on Modern Architecture". Architectural Glass Quarterly, 56(2), 112-125.

3. Lee, D., et al. (2023). "Innovations in Automotive Glass Manufacturing: The Role of Advanced Cutting Machines". International Journal of Automotive Engineering, 41(4), 301-315.

4. Zhang, X., & Wang, Y. (2022). "Optimizing Solar Panel Production through Advanced Glass Cutting Techniques". Renewable Energy Processing, 33(1), 45-59.