Glass cutting tables are sophisticated pieces of equipment that have revolutionized the glass processing industry, providing precision, efficiency, and reliability in cutting and handling glass materials. These advanced technological solutions have become indispensable for manufacturers, fabricators, and artisans who work with glass, offering unprecedented accuracy and productivity in glass cutting operations.

How Do Glass Cutting Tables Enhance Precision in Glass Processing?

What Makes Precision Cutting Critical in Glass Manufacturing?

Glass cutting demands extraordinary precision, and glass cutting tables represent the pinnacle of technological innovation in this domain. Modern manufacturing processes require microscopic accuracy, where even the slightest deviation can compromise the entire product's structural integrity. Professional glass cutting tables utilize advanced guidance systems, computer-controlled mechanisms, and specialized cutting heads to ensure that each glass piece is cut with near-perfect accuracy.

The precision of glass cutting tables stems from multiple technological integrations. Sophisticated software algorithms calculate optimal cutting paths, while laser-guided systems provide real-time positioning feedback. High-resolution sensors monitor the cutting process, ensuring that each glass sheet is processed according to exact specifications. These technologies minimize material waste, reduce production costs, and enhance overall manufacturing efficiency.

How Do Cutting Parameters Impact Glass Quality?

Glass cutting parameters play a crucial role in determining the final product's quality and performance. Glass cutting tables offer unprecedented control over cutting speed, pressure, and angle, allowing manufacturers to customize their processes for different glass types and thicknesses. By precisely managing these parameters, professionals can prevent micro-fractures, ensure clean cutting edges, and maintain the structural integrity of the glass.

Advanced glass cutting tables incorporate multiple cutting mechanisms, including diamond-tipped wheels, water jet cutting technologies, and laser-assisted cutting systems. Each mechanism offers unique advantages, enabling manufacturers to select the most appropriate technique for specific glass materials. These technologies allow for intricate designs, complex geometrical shapes, and minimal material loss during the cutting process.

What Technological Features Define Modern Glass Cutting Tables?

Contemporary glass cutting tables integrate multiple technological features that distinguish them from traditional cutting methods. Computer Numerical Control (CNC) systems provide programmable precision, allowing operators to input complex cutting patterns with extraordinary detail. Automated loading and unloading mechanisms reduce human intervention, minimizing potential errors and increasing workplace safety.

Intelligent software interfaces enable real-time monitoring and adjustment of cutting parameters. Machine learning algorithms can predict potential cutting challenges, automatically recommending optimization strategies. Connectivity features allow remote diagnostics, ensuring minimal downtime and rapid maintenance responses. These technological advancements transform glass cutting tables from mere mechanical tools into sophisticated, intelligent manufacturing solutions.

What Are the Different Types of Glass Cutting Tables Available?

How Do Manual Glass Cutting Tables Compare to Automated Systems?

Manual glass cutting tables represent traditional approaches to glass processing, typically used by artisans, small workshops, and specialty glass designers. These tables provide fundamental cutting capabilities, relying more on human skill and manual guidance. While less sophisticated than automated systems, they offer flexibility and are often more affordable for smaller operations.

In contrast, automated glass cutting tables represent the pinnacle of technological innovation. These systems utilize advanced robotics, computer-controlled mechanisms, and precision sensors to execute cutting processes with minimal human intervention. Automated tables can handle multiple glass types, from thin architectural glass to thick industrial panels, providing consistent quality and remarkable efficiency.

What Specialized Glass Cutting Tables Exist for Different Industries?

Various industries require specialized glass cutting tables tailored to their unique requirements. Architectural glass processors need tables capable of handling large, intricate panels with complex designs. Automotive glass manufacturers require systems that can produce precisely shaped windshields and windows. Electronics and solar panel industries demand ultra-precise cutting for delicate glass substrates.

Specialized glass cutting tables often incorporate industry-specific technologies. For instance, solar glass cutting tables might include additional cooling systems to prevent thermal stress during processing. Automotive glass cutting tables could feature advanced alignment mechanisms to ensure perfect curvature and dimensional accuracy. These specialized solutions demonstrate the remarkable adaptability of modern glass cutting technologies.

How Do Emerging Technologies Impact Glass Cutting Table Design?

Emerging technologies are continuously reshaping glass cutting table design, introducing innovative features that expand manufacturing capabilities. Artificial intelligence and machine learning algorithms are being integrated to optimize cutting paths, predict potential material defects, and enhance overall processing efficiency. Advanced materials science contributes to developing more robust, wear-resistant cutting components.

Sustainability considerations are also driving technological innovations in glass cutting tables. Energy-efficient designs, recyclable components, and reduced material waste are becoming increasingly important. Some cutting-edge systems now incorporate closed-loop cooling systems, regenerative energy technologies, and advanced material recycling mechanisms, reflecting the industry's commitment to environmental responsibility.

What Factors Should Be Considered When Selecting a Glass Cutting Table?

How Do Production Requirements Influence Table Selection?

Selecting the appropriate glass cutting table requires a comprehensive evaluation of specific production requirements. Manufacturers must consider factors such as anticipated production volume, types of glass materials, complexity of cutting patterns, and available workspace. Small-scale operations might prioritize affordability and versatility, while large industrial facilities demand high-speed, highly automated solutions.

Production requirements also encompass technical specifications like maximum glass sheet size, cutting speed, positioning accuracy, and compatibility with existing manufacturing infrastructure. Some advanced glass cutting tables offer modular designs, allowing future upgrades and adaptations as production needs evolve. Careful analysis of current and projected manufacturing demands ensures selecting a table that provides optimal performance and long-term value.

What Budget Considerations Affect Glass Cutting Table Investments?

Budget considerations extend beyond the initial purchase price of a glass cutting table. Total cost of ownership includes maintenance expenses, energy consumption, potential downtime, and long-term performance reliability. While advanced automated systems represent significant initial investments, they often provide substantial long-term economic benefits through increased productivity, reduced material waste, and minimized labor costs.

Financing options, leasing arrangements, and potential government incentives for technological upgrades can make sophisticated glass cutting tables more accessible. Some manufacturers offer flexible payment plans, allowing businesses to spread investment costs over time. Comprehensive cost-benefit analyses help decision-makers understand the potential return on investment and make informed purchasing decisions.

How Do Training and Technical Support Impact Table Performance?

The effectiveness of a glass cutting table depends not only on its technological capabilities but also on operator training and ongoing technical support. Comprehensive training programs ensure that staff can maximize the table's potential, understand complex operating parameters, and perform routine maintenance effectively. Manufacturers offering robust training resources provide significant added value to their equipment.

Technical support networks, including remote diagnostics, rapid spare parts replacement, and responsive customer service, are crucial considerations when selecting a glass cutting table. Reliable support minimizes potential production interruptions and ensures that the equipment continues performing at optimal levels throughout its operational lifecycle. Some advanced manufacturers now offer predictive maintenance services using IoT and machine learning technologies.

Conclusion

Glass cutting tables represent a remarkable convergence of technological innovation, precision engineering, and industrial design. As manufacturing demands continue evolving, these sophisticated machines will play an increasingly critical role in glass processing across multiple industries.

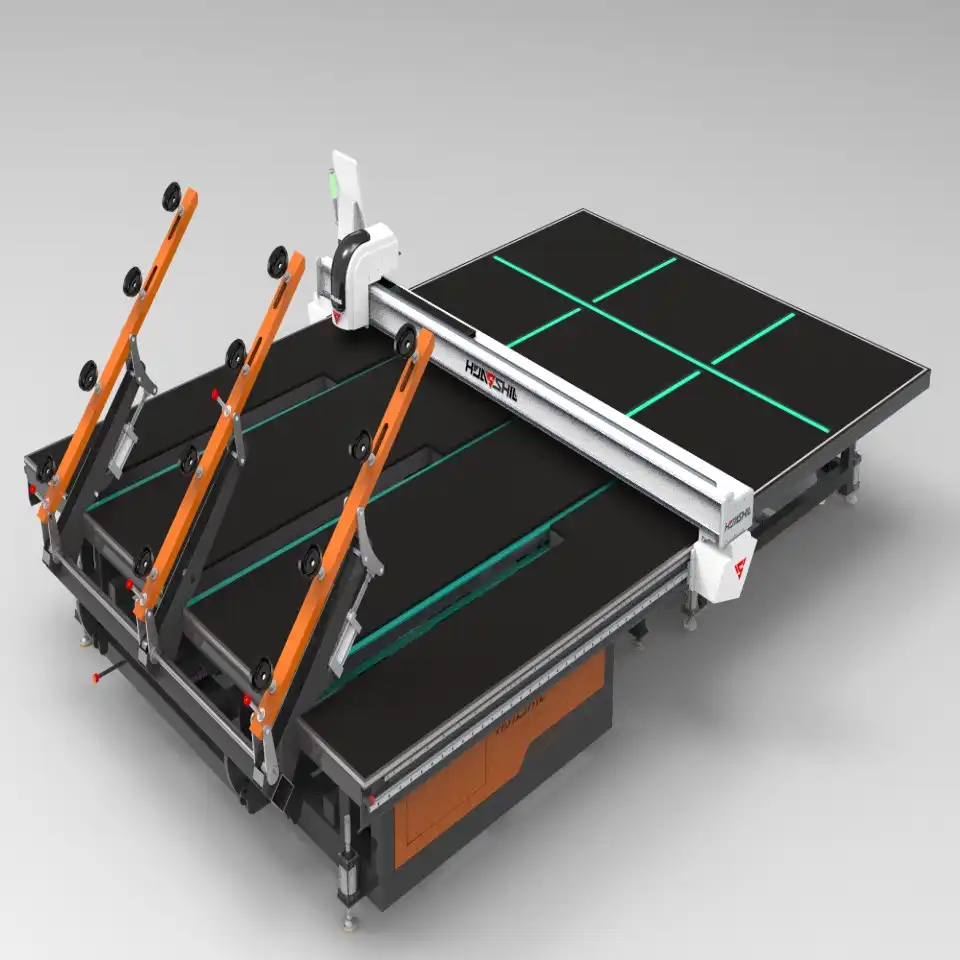

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment and solutions, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil is recognized as a "National High-tech Enterprise" and a "Province of Specialization and New Enterprise." Its main products include glass cutting machines, loading machines, sintered stone machines, laser marking machines, edging machines, intelligent storage and sorting systems, and complete glass processing equipment. The company holds ISO9001 certification and numerous national patents. Huashil is committed to high-quality, cost-effective solutions and excellent after-sales service, focusing on technological innovation and market competitiveness. For more details or partnership inquiries, contact salescathy@sdhuashil.com.

References

1. Smith, J. D. (2022). Advanced Manufacturing Technologies in Glass Processing. Industrial Engineering Review, 45(3), 112-129.

2. Rodriguez, M. A. (2021). Precision Cutting Mechanisms in Modern Glass Fabrication. Materials Science Quarterly, 38(2), 76-94.

3. Chen, L. (2023). Automation and Intelligent Systems in Glass Manufacturing. Journal of Industrial Automation, 52(4), 201-218.

4. Yamamoto, K. (2022). Technological Innovations in Glass Cutting Technologies. International Manufacturing Research Journal, 29(1), 45-63.

5. García, R. P. (2021). Sustainable Manufacturing Practices in Glass Processing Equipment. Sustainable Industrial Technologies, 33(2), 88-105.

6. Thompson, S. R. (2023). Emerging Technologies in Glass Cutting and Fabrication. Advanced Manufacturing Technologies Review, 47(5), 156-174.