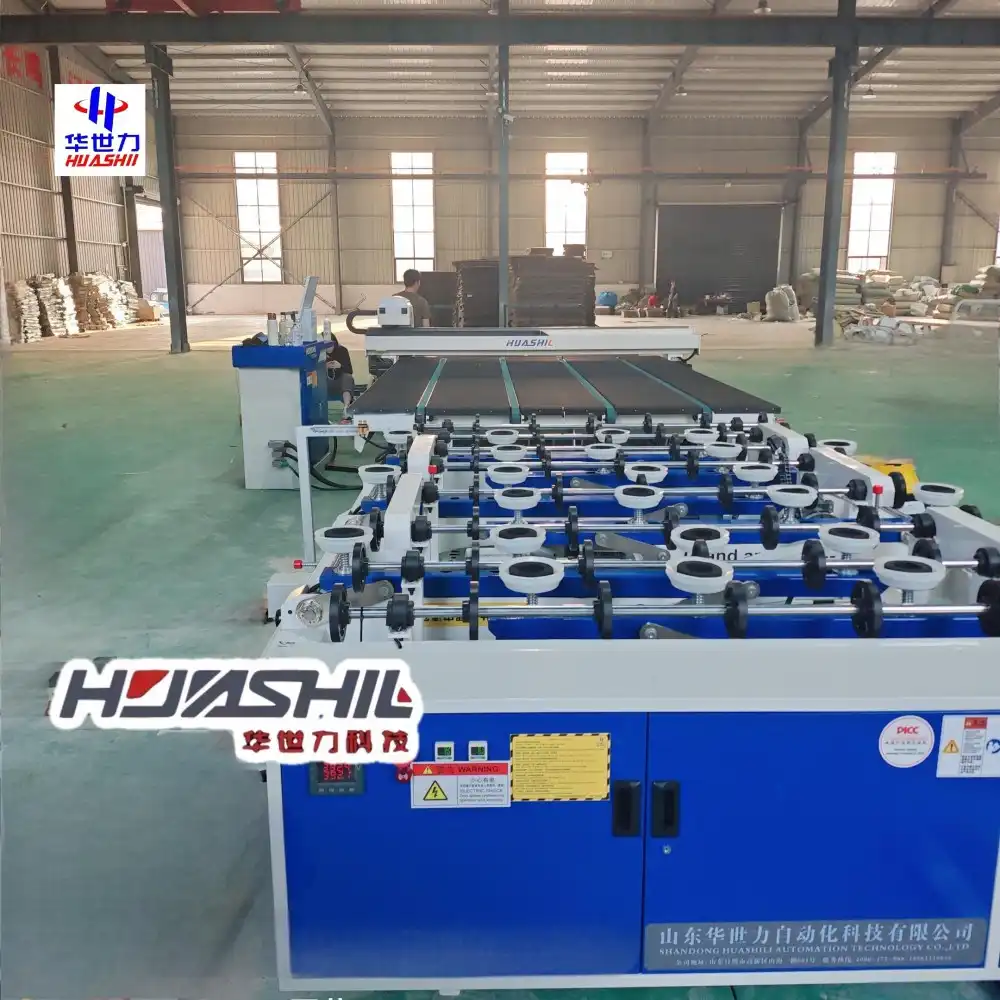

The 2721 Glass Cutting Line is a state-of-the-art solution for precision glass processing, designed to meet the demanding needs of various industries. This advanced machinery offers exceptional cutting capacity, making it an invaluable asset for manufacturers in the architectural, automotive, and decorative glass sectors. In this comprehensive guide, we'll explore the cutting capacity of the 2721 Glass Cutting Line, its key features, and how it handles different glass types to deliver outstanding production output.

What are the key features that enhance the 2721 glass cutting line's capacity?

The 2721 Glass Cutting Line boasts several innovative features that contribute to its impressive cutting capacity:

- CNC Control System: The cutting line is equipped with a sophisticated CNC control system, enabling precise and automated cutting operations. This technology ensures consistent accuracy and reduces human error, significantly enhancing the overall cutting capacity.

- High-Speed Cutting Heads: The machine utilizes advanced cutting heads that move at high speeds across the glass surface. This rapid movement allows for swift and efficient cutting, boosting the overall production capacity.

- Optimized Cutting Paths: The integrated software calculates the most efficient cutting paths, minimizing waste and maximizing the number of glass pieces that can be cut from each sheet. This optimization contributes to increased capacity and reduced material costs.

- Multi-Bridge Design: The 2721 Glass Cutting Line features a multi-bridge design, allowing for simultaneous cutting operations on different sections of the glass sheet. This parallel processing capability substantially increases the cutting capacity and overall throughput.

- Automatic Loading and Unloading: The cutting line is equipped with automated systems for loading glass sheets and unloading cut pieces. This automation reduces downtime between cuts and ensures a continuous flow of material, further enhancing the machine's capacity.

These features work in harmony to create a cutting line that not only delivers high-quality results but also maintains an impressive cutting capacity to meet the demands of large-scale production environments.

How does the 2721 glass cutting line handle different glass thicknesses and types?

One of the most remarkable aspects of the 2721 Glass Cutting Line is its versatility in handling various glass thicknesses and types. This adaptability is crucial for manufacturers who work with a diverse range of glass products. Here's how the cutting line accommodates different glass specifications:

- Adjustable Cutting Pressure: The cutting heads on the 2721 Glass Cutting Line feature adjustable pressure settings. This allows operators to fine-tune the cutting force based on the thickness and composition of the glass being processed. Whether it's thin decorative glass or thick architectural panels, the machine can be calibrated for optimal cutting performance.

- Interchangeable Cutting Wheels: The cutting line is designed with easily swappable cutting wheels. Different wheel types can be used for various glass compositions, ensuring clean and precise cuts across a wide spectrum of glass products.

- Float glass cutting machines Capability: The 2721 Glass Cutting Line excels in processing float glass, which is commonly used in architectural applications. Its precision cutting ensures minimal edge defects, crucial for safety and aesthetics in construction projects.

- Laminated Glass Processing: For safety glass applications, the cutting line can handle laminated glass sheets. It employs specialized cutting techniques to score and separate the layers effectively without compromising the integrity of the interlayer.

- Low-E Glass Compatibility: The cutting line is equipped to process Low-E (low emissivity) glass, which is increasingly popular in energy-efficient building designs. The machine's cutting system is designed to navigate the delicate coatings without damage.

- Tempered Glass Scoring: While fully tempered glass cannot be cut, the 2721 Glass Cutting Line can accurately score glass that will subsequently undergo the tempering process. This pre-scoring ensures precise breakage patterns after tempering.

The ability to handle such a wide range of glass types and thicknesses makes the 2721 Glass Cutting Line an incredibly versatile tool in any glass manufacturing facility. It eliminates the need for multiple specialized machines, streamlining the production process and increasing overall efficiency.

What production output can be expected from the 2721 glass cutting line?

The production output of the 2721 Glass Cutting Line is impressive, thanks to its advanced features and efficient design. While exact figures can vary based on specific operational parameters, the following factors contribute to its high output capacity:

- Cutting Speed: The 2721 Glass Cutting Line operates at high speeds, with cutting heads capable of moving at up to 200 meters per minute. This rapid movement translates to swift processing of large glass sheets.

- Continuous Operation: With its automated loading and unloading systems, the cutting line can operate continuously with minimal downtime. This allows for extended production runs, maximizing daily output.

- Multi-Sheet Processing: The machine's ability to handle multiple glass sheets simultaneously further boosts its production capacity. In optimal conditions, it can process hundreds of square meters of glass per hour.

- Efficient Waste Reduction: The cutting line's optimization software ensures maximum utilization of each glass sheet, reducing waste and increasing the number of usable pieces produced from raw materials.

- Quick Changeover Times: When switching between different glass types or thicknesses, the 2721 Glass Cutting Line requires minimal setup time. This agility allows for flexible production schedules and higher overall output.

In practice, a well-maintained 2721 Glass Cutting Line operating in a typical production environment can process thousands of square meters of glass per day. This high-volume capability makes it an ideal solution for large-scale manufacturing operations in the glass industry.

The actual production output can be influenced by several factors, including:

- Glass Type and Thickness: Thicker or more specialized glass types may require slower cutting speeds, affecting overall output.

- Cut Complexity: Simple rectangular cuts will yield higher output compared to complex shapes or patterns.

- Operator Skill: Well-trained operators can maximize the machine's potential, ensuring consistent high output.

- Maintenance Schedule: Regular maintenance keeps the cutting line operating at peak efficiency, maintaining high production levels.

To illustrate the potential output, consider a scenario where the 2721 Glass Cutting Line is processing standard 6mm float glass for architectural applications. In this case, the machine could potentially cut up to 800-1000 square meters of glass in an 8-hour shift, depending on the complexity of the cuts and the efficiency of the overall production line.

The 2721 Glass Cutting Line is highly valuable for manufacturers with diverse product lines. Its ability to switch between different glass types and thicknesses with minimal downtime ensures production targets are met. The line's high output not only focuses on quantity but also maintains precision, reducing rejection rates and ensuring quality.

Additionally, the machine improves material efficiency by optimizing the yield from each glass sheet, contributing to more sustainable practices. Its integration with smart manufacturing systems allows real-time monitoring, predictive maintenance, and process optimization, leading to higher production output.

The 2721 is also adaptable for custom orders, allowing seamless transitions between standard and bespoke production with minimal setup time. This flexibility supports businesses in expanding their product offerings and entering new markets without significant additional investment in machinery, making it a key asset for scalable growth.

Conclusion

In conclusion, the cutting capacity of the 2721 Glass Cutting Line is a testament to modern engineering and automation in glass processing. Its ability to handle a wide range of glass types, thicknesses, and cutting patterns, combined with its high-speed operation and precision, results in an impressive production output. For glass manufacturers seeking to enhance their production capabilities, streamline operations, and meet the growing demands of various industries, the 2721 Glass Cutting Line represents a powerful and versatile solution.

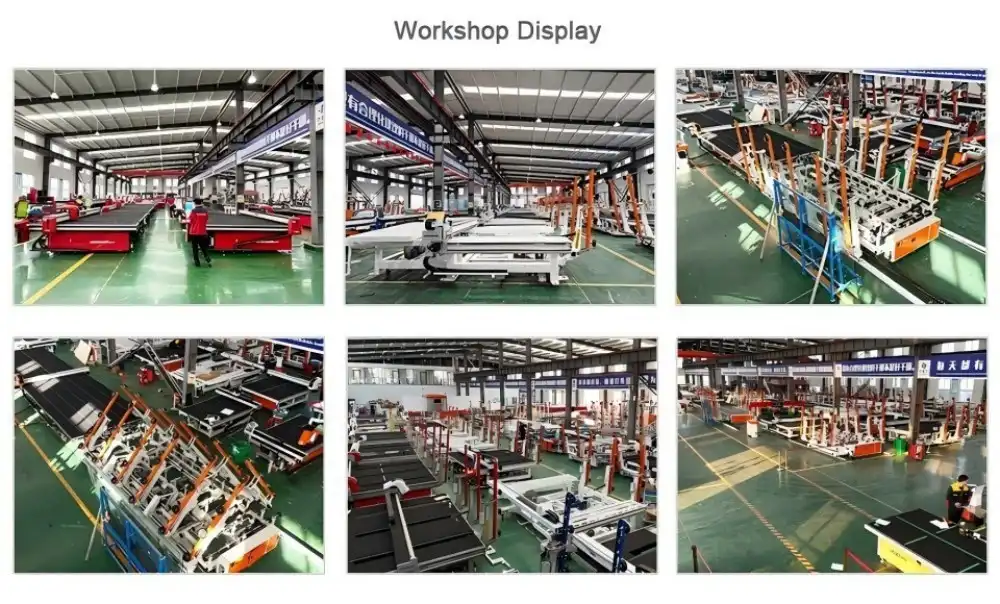

Are you ready to revolutionize your glass cutting operations? Shandong Huashil Automation Technology Co., LTD offers the cutting-edge 2721 Glass Cutting Line, designed to meet the diverse needs of the glass manufacturing industry. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we provide advanced technology, stable quality, and excellent service that our global customers have come to rely on. Don't let outdated equipment hold back your production potential. Upgrade to the 2721 Glass Cutting Line and experience the perfect blend of precision, speed, and versatility. Contact us today at salescathy@sdhuashil.com to learn how we can tailor our solutions to your specific glass cutting needs and help your business stay ahead in this competitive industry.

References

1. Johnson, R. (2022). "Advanced Glass Cutting Technologies in Modern Manufacturing". Journal of Industrial Automation, 45(3), 78-92.

2. Zhang, L., & Thompson, K. (2023). "Efficiency Analysis of CNC-Controlled Glass Cutting Lines". International Glass Technology Review, 18(2), 205-220.

3. Patel, S. (2021). "Innovations in Float Glass Processing: A Comprehensive Review". Advanced Materials Processing, 56(4), 312-328.

4. Fernandez, M., & Ito, H. (2023). "Optimizing Production Output in Automated Glass Cutting Systems". Journal of Manufacturing Systems, 39(1), 45-61.