Product Category

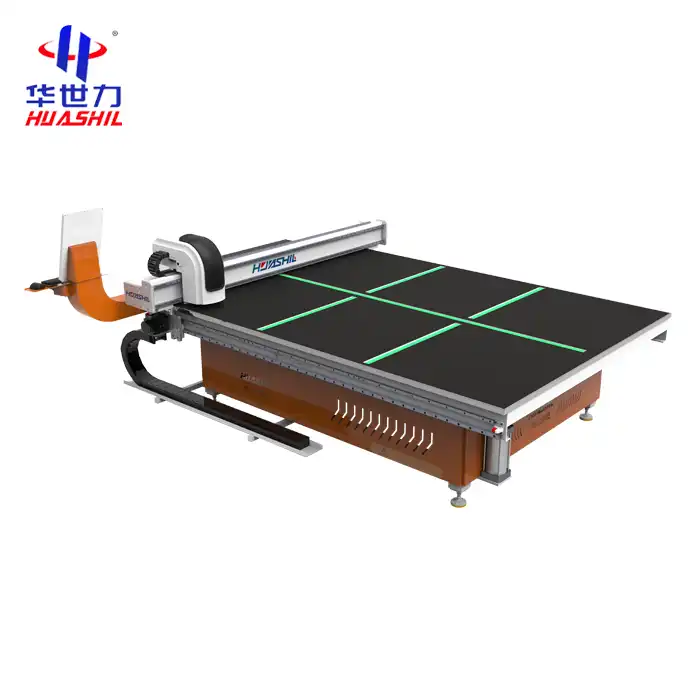

Mirror Loading And Cutting Machine Factory

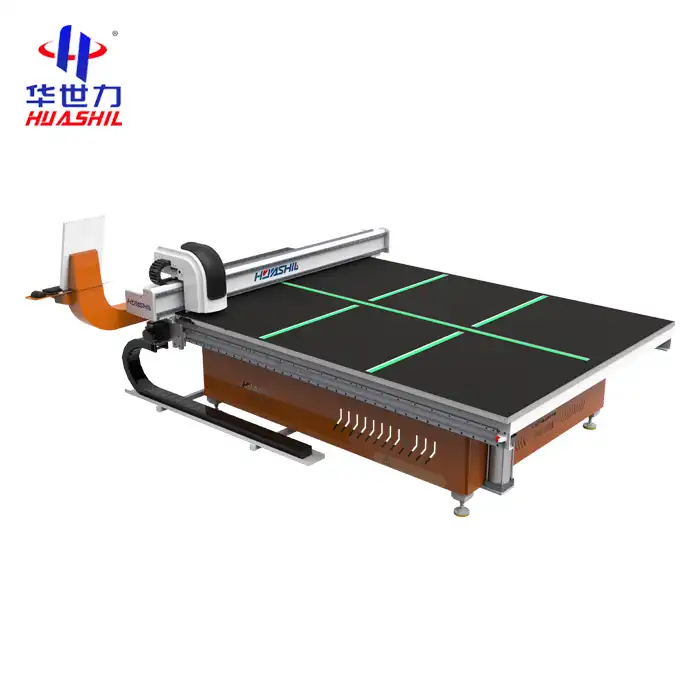

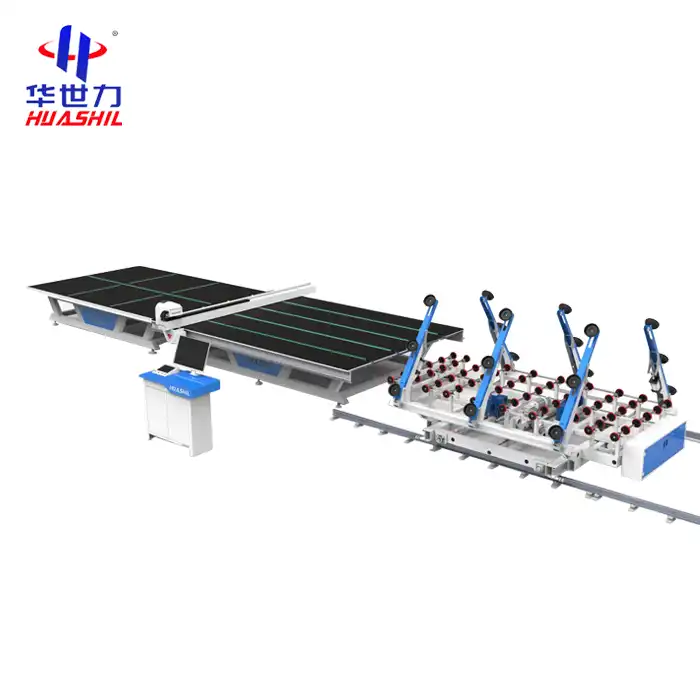

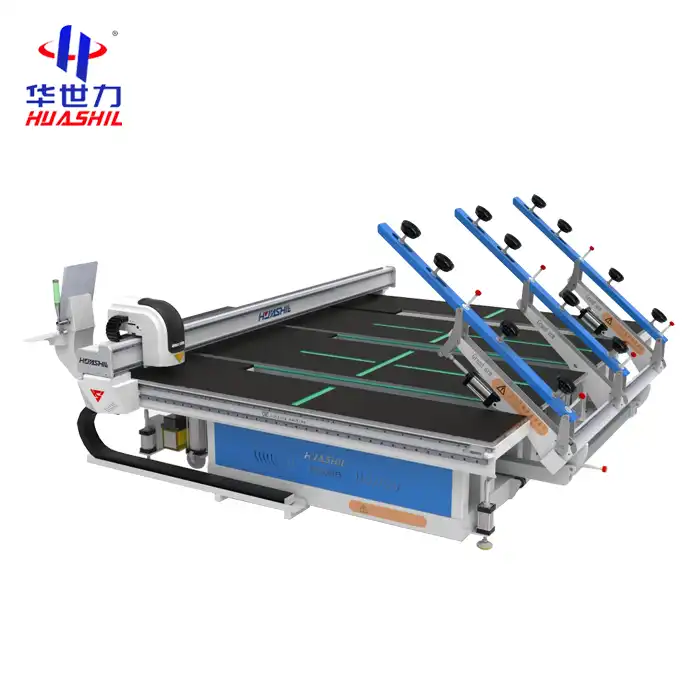

Precision mirror loading for modern manufacturing

The renowned **Mirror Loading and Cutting Machine Factory** Shandong Huashil Automation Technology Co. , Ltd.

provides sophisticated automation solutions for construction and glass processing.

Our precision engineering machines have automated loading/unloading systems, speeding up operations, reducing manual involvement, and improving cutting accuracy to ±0.1mm.

Customised Automation for Different Needs Our Mirror Loading and Cutting Machines accommodate tempered, laminated, and coated glass thicknesses from 3mm to 25mm and have customisable software.

The factory-direct model saves money without sacrificing ISO 9001 and CE quality.

Our solutions ensure smooth integration into high-volume manufacturing processes for skyscraper facades and interior design.

Why Partner With Us?

As a mirror loading and cutting machine factory, we value dependability and innovation.

Meeting commercial glass processing deadlines requires automated systems that minimise material waste and maximise production.

Customers get 24/7 technical assistance and adaptable designs that adapt to their needs.

Shandong Huashil redefines glass fabrication efficiency with cutting-edge technology and factory-direct advantages, trusted by worldwide manufacturers.

Related Products

-

small cnc glass cutting machine

1.Model:HSL-CNC2721

2.Max glass size:2700*2100mm

3.Glass cutting thickness:2-19mm

4.Dimension:3660*3185mm

5.Optimization software:Optima

6.Function: automatic pressure control,automatic edge finding,air flotation system, 360 degree remote control walking

7.Certificate:CE, ISO9001 -

CNC glass cutting machine

-

CNC3826 glass cutting machine

-

flat glass cutting machine

-

Automatic shaped glass cutting machine

Precision mirror loading for contemporary manufacturing

Shandong Huashil Automation Technology Co. , Ltd., the famous Mirror Loading and Cutting Machine Factory, offers advanced construction and glass processing automation solutions.

Automated loading/unloading systems on our precise engineering equipment enhance speed, reduce operator participation, and enhance cutting accuracy to ±0.1mm.

Need-Specific Automation Our Mirror Loading and Cutting Machines can handle 3mm to 25mm tempered, laminated, and coated glass and have unique software.

The factory-direct solution saves money without compromising ISO 9001 and CE.

Our products integrate smoothly into high-volume skyscraper facade and interior design manufacturing.

Partnership with Us: Why?

As a mirror loading and cutting machine factory, we prioritise reliability and innovation.

Automated technologies that reduce waste and boost output are needed to meet commercial glass processing requirements.

Customers receive 24/7 technical support and customisable designs.

Global manufacturers trust Shandong Huashil's cutting-edge technology and factory-direct advantages to improve glass manufacturing efficiency.

Modern manufacturing precision mirror loading Famous

Mirror Loading and Cutting Machine Factory Shandong Huashil Automation Technology Co. , Ltd.

provides innovative construction and glass processing automation solutions.

Our precision engineering equipment has automated loading/unloading systems that improve speed, eliminate operator involvement, and improve cutting accuracy to ±0.1mm.

Automation for Needs Our Mirror Loading and Cutting Machines feature unique software and can handle 3mm to 25mm tempered, laminated, and coated glass.

The factory-direct option saves money without sacrificing ISO 9001 and CE.

We seamlessly integrate our goods into high-volume skyscraper façade and interior design manufacturing.

Why Partner with Us?

As a mirror loading and cutting machine factory, we value dependability and innovation.

Commercial glass production requires automated waste-reduction and output-boosting systems.

Custom designs and 24/7 technical assistance are available.

Global manufacturers trust Shandong Huashil's cutting-edge technology and factory-direct advantages to boost glass manufacturing efficiency.

FAQs

1. What technical specs describe your Mirror Loading and Cutting Machines?

Precision servo motors, laser-guided alignment, and 1200 mm/s cutting rates are on our machines. Designed for 3mm-25mm glass thicknesses, they offer ±0.1mm precision and little edge chipping. Built with industrial-grade components, they fit tempered, laminated, and coated mirrors.

2. How does your factory's manufacturing skills assure reliability?

We use modular engineering and ISO 9001-certified methods for 15+ years in glass automation. We stress load arms and cutting blades to optimise performance for high-volume manufacturing.

3. What quality controls do you use?

All machines undergo raw material checks, assembly-line testing, and 48-hour operational simulations. Real-time pressure sensor and cutting accuracy data records with a 2-year guarantee.

4. Can I customise manufacturing for special needs?

Absolutely. Flexible conveyor widths (800-3000mm), configurable cutting patterns, and CNC integration are available. We customise curved mirrors, anti-reflective coatings, and safety glass shapes.

5. How do I order a machine?

Our manufacturer offers free consultations. Share your production goals and we'll customise a proposal with 3D models, lead times, and onsite training. 12 business-hour responses guaranteed.

Best Selling Products

-

CNC glass cutting machine

-

CNC3826 glass cutting machine

-

3829 glass cutting machine

-

glass auto cutting machine

-

furniture cabinet glass cutting machine

-

manual glass loading machine

Related Blogs

- How Do You Maintain a CNC Mirror Cutting Machine?

- What is a Mobile Glass Cutting Machine?

- How Accurate is a CNC Glass Cutting Assembly Line?

- How is a Glass Deep Cutting Machine Different from a Standard Cutting Machine?

- How Do I Choose the Right Glass Processing Equipment for My Business?

- Can Glass Manufacturing Equipment Be Customized for Different Production Needs?

Related Search

- cnc Glass Cutting Assembly Line Manufacturer

- Jumbo glass cutting machine Manufacturer

- glass breaking table Manufacturer

- CNC glass cutting machine Manufacturer

- CNC3826 glass cutting machine Manufacturer

- 3829 glass cutting machine Manufacturer

- glass auto cutting machine Manufacturer

- furniture cabinet glass cutting machine Manufacturer

- manual glass loading machine Manufacturer

- mobile glass cutter machine Manufacturer

- industrial glass cutting and laminating systems Manufacturer

- automatic double glass processing machine Manufacturer

- glass transport table line Manufacturer

- glass cut outs machine Manufacturer

- high quality mirror processing machine Manufacturer

- mobile glass cutter Manufacturer

- cutting laminated glass machine Manufacturer

- automatic glass cutter Manufacturer

- air flotation table Manufacturer

- furniture cutting equipment Manufacturer

- Float Glass Double Machinery Manufacturer

- Special Shape Sintered Stone Cutting Machines Manufacturer

- Automatic Cnc Glass Loading Machine Manufacturer

- High-Performance Glass Processing Equipment Manufacturer

- Glass Measure Table Machine Manufacturer

- Industrial Glass Cutting Table Manufacturer

- Glass Industry Air Flotation Machine Manufacturer

- Gtm Glass Loading Machine Manufacturer

- Glass Sheet Loader Manufacturer

- Reasonable Price Glass Loading Table Manufacturer

- Automated Glass Processing Manufacturer

- Automated Glass Processing Systems Manufacturer

- Glass Cnc Cut Out Machine Manufacturer

- Furniture Glass Machine Manufacturer

- Glass Loader Manufacturer

- Glass Loading Table With Arm Manufacturer

- Glass Cutting Line Manufacturer

- Glass Sheet Storage Cutting Line Manufacturer

- Electric Glass Sheet Storage Rack Manufacturer

- Glass Cutting Line Machine Manufacturer

- 2721 Glass Cutting Line Manufacturer

- Cnc Glass Cutting Line Manufacturer

- Auto Glass Cutting Line Machine Manufacturer

- Automatic Glass Cutting Line Manufacturer

- Glass Cutting Assembly Line Manufacturer

- Float Glass Cutting Machine Manufacturer

- Automatic Glass Cutting Assembly Line Manufacturer

- Glass Processing Equipment Manufacturer

- Glass Manufacturing Equipment Manufacturer

- Glass Cutting Loading Machine Manufacturer

- 5133 Glass Cutting Line Manufacturer

- Low E Glass Edge Deletion Machine Manufacturer

- Automatic Glass Cutting Line For Low-E Glass Manufacturer

- Industrial Glass Cutting Machine Manufacturer

- Professional Glass Cutting Machine Manufacturer

- Industrial Glass Breaking Equipment Manufacturer

- Custom Glass Loading Machine Manufacturer

- Automatic Glass Loading Machine Manufacturer

- Air Float Glass Loading Table Manufacturer

- All In One Glass Cutting Machine Manufacturer

- Glass Grinding Equipment Manufacturer

- Automatic Glass Grinding Machine Manufacturer

- Flat Glass Cutting Machine Manufacturer

- Round Glass Grinding Machine Manufacturer

- Automatic Shaped Glass Cutting Machine Manufacturer

- Glass Double Edging Machine Manufacturer

- Glass Cutting Equipment Manufacturer

- Glass Edge Grinding Machine Manufacturer

- Glass Double Edger Machine Manufacturer

- Double Edger Machine Manufacturer

- Glass Bilateral Edging Machine Manufacturer

- Mirror Loading And Cutting Machine Manufacturer

- Cnc Mirror Cutting Machine Manufacturer

- Cnc Glass Loading Cutting Breaking Machine Manufacturer

- Window Glass Cutting Machine Manufacturer

- Float Glass Cutting Equipment Manufacturer

- Cnc Glass Cutting Equipment Manufacturer

- Cnc Shaped Glass Cutting Machine Manufacturer

- Cnc Glass Machine Manufacturer

- Fast Speed Glass Cutting Machine Manufacturer

- Commercial Glass Cutting Machine Manufacturer

- 3826 Glass Cutting Machine Manufacturer

- Cutting Machine For Stained Glass Windows Manufacturer

- Mobile Glass Cutting Machine Manufacturer

- Glass Deep Cutting Machine Manufacturer

- Integrated Glass Cutting Machine Manufacturer

- Glass Cutting Table Manufacturer

- Small Glass Cutting Machine Manufacturer

- Glass Cutting Table Machine Manufacturer

- Automatic Glass Breaking Machine Manufacturer

- Small Cnc Glass Cutting Machine Manufacturer

- Cnc Stone Cutting Machine Manufacturer

- Portable Tile Cutting Machine Manufacturer

- Large Tile Cutting Machine Manufacturer

- Automatic Stone Cutting Machine Manufacturer

- Sintered Stone Cutting Machine Manufacturer

- Best Stone Cutting Machine Manufacturer

- Special Shape Sintered Stone Cutting Machine Manufacturer

- Cnc Sintered Stone Cutting Machine Manufacturer

- Glass Storage Racks Manufacturer

- Glass Loading Table Manufacturer

- Shuttle Car Manufacturer

- Intelligent Manufacturing Mes System Manufacturer

- Intelligent Glass Storage System Manufacturer

- Mini Glass Cutting Machine Manufacturer

- Small Glass Cutting Machinery Manufacturer

- Cnc Glass Machinery Manufacturer

- Cnc Glass Processing Machine Manufacturer

- Glass Cnc Cutting Machine Manufacturer

- Glass Processing Machine Manufacturer

- Window Cutting Machine Manufacturer

- Cnc Glass Equipment Manufacturer

- Laser Marking Machine Manufacturer

- Laser Marking And Cutting Machine Manufacturer

- Double Side Glass Cutting Line Manufacturer

- Double Turn Loading Glass Cutting Line Manufacturer

- Cnc Control Glass Cutting Line Manufacturer

- Glass Production Line Manufacturer

- Glass Air Float Loading Table Manufacturer

- Semi Automatic Glass Loading Machine Manufacturer

- Cnc Glass Cutting Assembly Line Factory

- Jumbo Glass Cutting Machine Factory

- Glass Breaking Table Factory

- Cnc Glass Cutting Machine Factory

- Cnc3826 Glass Cutting Machine Factory

- 3829 Glass Cutting Machine Factory

- Glass Auto Cutting Machine Factory

- Furniture Cabinet Glass Cutting Machine Factory

- Manual Glass Loading Machine Factory

- Industrial Glass Cutting And Laminating Systems Factory

- Automatic Double Glass Processing Machine Factory

- Glass Transport Table Line Factory

- Glass Cut Outs Machine Factory

- High Quality Mirror Processing Machine Factory

- Mobile Glass Cutter Factory

- Cutting Laminated Glass Machine Factory

- Automatic Glass Cutter Factory

- Air Flotation Table Factory

- Furniture Cutting Equipment Factory

- All In One Glass Cutting Machine Factory

- Float Glass Double Machinery Factory

- Special Shape Sintered Stone Cutting Machines Factory

- Automatic Cnc Glass Loading Machine Factory

- High-Performance Glass Processing Equipment Factory

- Glass Measure Table Machine Factory

- Industrial Glass Cutting Table Factory

- Glass Industry Air Flotation Machine Factory

- Gtm Glass Loading Machine Factory

- Glass Sheet Loader Factory

- Reasonable Price Glass Loading Table Factory

- Automated Glass Processing Factory

- Automated Glass Processing Systems Factory

- Glass Loader Factory

- Glass Loading Table With Arm Factory

- Glass Cutting Line Factory

- Glass Sheet Storage Cutting Line Factory

- Electric Glass Sheet Storage Rack Factory

- Glass Cutting Line Machine Factory

- 2721 Glass Cutting Line Factory

- Cnc Glass Cutting Line Factory

- Auto Glass Cutting Line Machine Factory

- Automatic Glass Cutting Line Factory

- Glass Cutting Assembly Line Factory

- Float Glass Cutting Machine Factory

- Automatic Glass Cutting Assembly Line Factory

- Glass Processing Equipment Factory

- Glass Cutting Loading Machine Factory

- 5133 Glass Cutting Line Factory

- Low E Glass Edge Deletion Machine Factory

- Professional Glass Cutting Machine Factory

- Industrial Glass Breaking Equipment Factory

- Custom Glass Loading Machine Factory

- Automatic Glass Loading Machine Factory

- Glass Grinding Equipment Factory

- Automatic Glass Grinding Machine Factory

- Flat Glass Cutting Machine Factory

- Round Glass Grinding Machine Factory

- Glass Double Edging Machine Factory

- Glass Cutting Equipment Factory

- Glass Edge Grinding Machine Factory

- Glass Double Edger Machine Factory

- Double Edger Machine Factory

- Glass Bilateral Edging Machine Factory

- Mirror Loading And Cutting Machine Factory

- Cnc Mirror Cutting Machine Factory

- Cnc Glass Loading Cutting Breaking Machine Factory

- Door Glass Cutting Machine Factory

- Float Glass Cutting Equipment Factory

- Cnc Shaped Glass Cutting Machine Factory

- Cnc Glass Machine Factory

- Fast Speed Glass Cutting Machine Factory

- Commercial Glass Cutting Machine Factory

- 3826 Glass Cutting Machine Factory

- Cutting Machine For Stained Glass Windows Factory

- Mobile Glass Cutting Machine Factory

- Glass Deep Cutting Machine Factory

- Integrated Glass Cutting Machine Factory

- Stained Glass Cutting Machine Factory

- Glass Cutting Table Factory

- Glass Cutting Table Machine Factory

- Automatic Glass Breaking Machine Factory

- Small Cnc Glass Cutting Machine Factory

- Cnc Stone Cutting Machine Factory

- Glass Laser Marking Machine Factory

- Portable Tile Cutting Machine Factory

- Large Tile Cutting Machine Factory

- Automatic Stone Cutting Machine Factory

- Sintered Stone Cutting Machine Factory

- Best Stone Cutting Machine Factory

- Special Shape Sintered Stone Cutting Machine Factory

- Cnc Sintered Stone Cutting Machine Factory

- Glass Storage Racks Factory

- Glass Loading Table Factory

- Shuttle Car Factory

- Intelligent Manufacturing Mes System Factory

- Intelligent Glass Storage System Factory

- Small Glass Cutting Machinery Factory

- Cnc Glass Machinery Factory

- Cnc Glass Processing Machine Factory

- Glass Cnc Cutting Machine Factory

- Glass Processing Machine Factory

- Window Cutting Machine Factory

- Cnc Glass Equipment Factory

- Laser Marking Machine Factory

- Laser Marking And Cutting Machine Factory

- Glass Loading Machine Factory

- Double Side Glass Cutting Line Factory

- Auto Glass Cutting Line Factory

- Double Turn Loading Glass Cutting Line Factory

- Cnc Control Glass Cutting Line Factory

- Glass Production Line Factory

- Glass Air Float Loading Table Factory

- Semi Automatic Glass Loading Machine Factory

- Cnc Glass Cutting Assembly Line Supplier

- Jumbo Glass Cutting Machine Supplier

- Cnc Glass Cutting Machine Supplier

- Cnc3826 Glass Cutting Machine Supplier

- 3829 Glass Cutting Machine Supplier

- Furniture Cabinet Glass Cutting Machine Supplier

- Manual Glass Loading Machine Supplier

- Mobile Glass Cutter Machine Supplier

- Industrial Glass Cutting And Laminating Systems Supplier

- Automatic Double Glass Processing Machine Supplier

- Glass Cut Outs Machine Supplier

- High Quality Mirror Processing Machine Supplier

- Mobile Glass Cutter Supplier

- Cutting Laminated Glass Machine Supplier

- Automatic Glass Cutter Supplier

- Air Flotation Table Supplier

- All In One Glass Cutting Machine Supplier

- Float Glass Double Machinery Supplier

- Special Shape Sintered Stone Cutting Machines Supplier

- Automatic Cnc Glass Loading Machine Supplier

- High-Performance Glass Processing Equipment Supplier

- Glass Measure Table Machine Supplier

- Industrial Glass Cutting Table Supplier

- Glass Industry Air Flotation Machine Supplier

- Gtm Glass Loading Machine Supplier

- Reasonable Price Glass Loading Table Supplier

- Automated Glass Processing Supplier

- Automated Glass Processing Systems Supplier

- Glass Cnc Cut Out Machine Supplier

- Furniture Glass Machine Supplier

- Glass Loader Supplier

- Glass Loading Table With Arm Supplier

- Glass Sheet Storage Cutting Line Supplier

- Electric Glass Sheet Storage Rack Supplier

- Glass Cutting Line Machine Supplier

- 2721 Glass Cutting Line Supplier

- Cnc Glass Cutting Line Supplier

- Auto Glass Cutting Line Machine Supplier

- Automatic Glass Cutting Line Supplier

- Glass Cutting Assembly Line Supplier

- Float Glass Cutting Machine Supplier

- Automatic Glass Cutting Assembly Line Supplier

- Glass Processing Equipment Supplier

- Glass Manufacturing Equipment Supplier

- Glass Cutting Loading Machine Supplier

- 5133 Glass Cutting Line Supplier